- Model NO.:

- AYJ-CXG100

- Certification:

We are a provider of medical consumables production equipments.

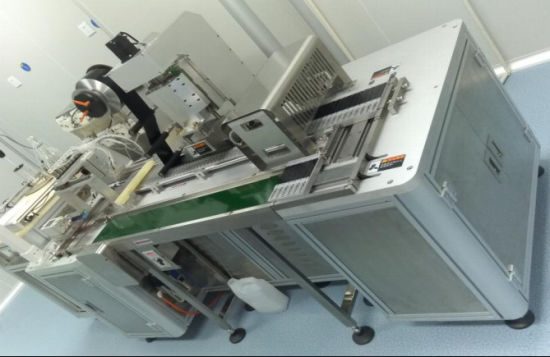

1.The Technological Process for Immunofluorescence reagent strip Assembly Line

1.1 Layering and leakage detection station

1.2 Reagent feed station

1.3 Reagents packaging station

1.4Film feeding station

1.5 Aluminium film sealing station

1.6 Aluminum film cutting molding station

1.1Layering and leakage detection station

(1) the station can detect whether the fixture is installed in reverse and whether the reagent bar is missing.

(2) this station can be used to flaten the reagent bar which is slightly uneven after the tooling bar.

(3) if the device alarms if the jig is installed inversely and the reagent bar is missing, the station will be suspended from work and reset to continue operation after manual treatment.

1.2 Reagent feed station

(1) provide mixing function; Need to avoid light reagents in the tank, pipe, consider the appropriate way to avoid light; According to the characteristics of magnetic beads, the materials we choose such as agitating paddle, pipe and filling needle do not affect the performance of magnetic bead suspension.

(2) it contains the function of liquid level induction. If the reagent in the liquid storage tank is reduced to the marked liquid level, the function of equipment prompt will be adopted to avoid the leakage of reagents.

1.3 Reagents packaging station

1) reagent filling station provides 8 channels for reagent filling at the same time.

(2) the accuracy of reagents can be achieved at the separation station: the accuracy is 50ul±5% and 100ul±3%.

(3) each pipeline has the function of flushing and emptying, and the reagent emptying channel is reserved. The pipeline is easy to be dismantled and replaced, and the cleaning is convenient.

(4) provide mixing function; Need to avoid light reagents in the tank, pipe, consider the appropriate way to avoid light; According to the characteristics of magnetic beads, the materials we choose such as agitating paddle, pipe and filling needle do not affect the performance of magnetic bead suspension.The height and speed of the filling can be adjusted to reduce the bubble in the filling process

1.4 Film feeding station

(1) the station is simple to replace the aluminum film and easy to operate.

(2) the film feeding mechanism can be customized according to the needs, which can be compatible with multiple types of films

1.5 Aluminium film sealing station

(1) the membrane feeding module transports the aluminum membrane to the reagent strip respectively.

(2) select reliable constant temperature device, pressure device and time controller. Meet the requirements of constant temperature, adjustable temperature, adjustable pressure, manual debugging, convenient sampling inspection.

(3) the hot pressing head is customized according to the shape of the reagent hole, and the heating is uniform, which can fix the edge of the reagent strip sealing film by hot pressing.

1.6 Aluminum film cutting molding station

(1) this station can quickly cut the aluminum film, the speed is fast, the aluminum film can be cut in a short time.

(2) after cutting the aluminum film, the finished aluminum film can be rolled down to the edge, with a flat edge and no warping.

The1year

The1year