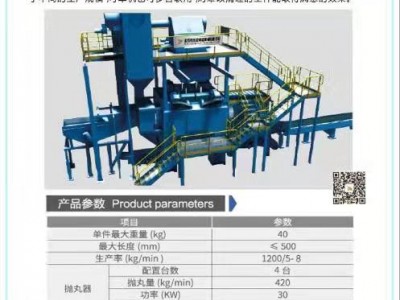

- Power:

- 56 kW

- Dust emissioin:

- 20 mg

- Efficiency:

- 2000 kG/3-8 min

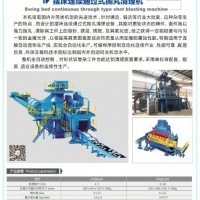

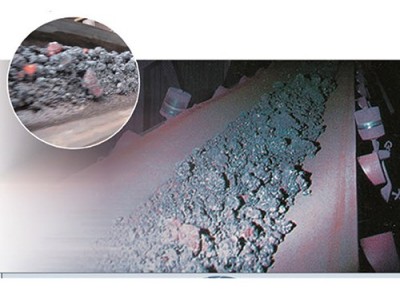

The QZ3118 drum type shot blasting machine has a high degree of automation and good cleaning effect. It can be used in a stand-alone operation or in conjunction with an assembly line to achieve full automation in the true sense. The workpiece of the drum shot blasting machine is automatically turned over and cleaned in the cleaning area, with reliable operation and high production efficiency. The main features of this machine are as follows: 1. This machine is mainly suitable for surface cleaning of various batch castings, forgings and aluminum alloy parts to remove the sticky sand and oxide layer on the surface for surface shot blasting treatment. 2. The shot blasting wheel is an important part of this equipment. The machine is manufactured with imported American technology. After years of production and verification, it operates reliably and has a good cleaning effect. The centrifugal high-efficiency and energy-saving shot blasting machine is used to throw the projectile at a high linear speed of 81m/s. 3. The machine adopts the overturning hopper type loading and unloading, the maximum loading is 1.2m³ (about 2 tons) at a time, the thrown projectile hits the workpiece, the workpiece is automatically turned over, and the workpiece is cleaned in 3-8 minutes. 4. The drum rotation mechanism adopts advanced dual drive technology, stable performance and reliable quality. 5. The inner drum shell is made of 16mm thick rolled Mn13 high wear-resistant steel plate, with a service life of more than 15,000 hours. 6. The hoist adopts the imported technology and adopts the wheel plate structure to prevent the belt from slipping, which greatly improves the efficiency and service life. 7. The machine can be connected with the production line. Between the machine and the production line, there is an automatic workpiece conveying system, which saves labor and reduces operating costs.

The1year

The1year