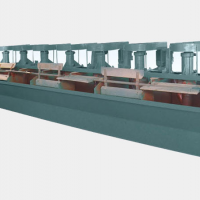

Disc surface grinder is a special machine tool used for surface processing of friction materials of vehicle disc brake pads. It is applicable to the grinding of various types of disc, which can ensure the roughness of friction surface and the parallelism of steel back surface. The special structure (annular groove) on the disc is suitable for grinding disc brake pads with boss steel back.

Before work, open the air source and dust suction air source required for dust blowing, then activate the electromagnetic suction cup, speed regulating motor and abrasive motor, adjust the speed of the magnetic suction cup and the height of the abrasive as required, and place the workpiece with steel back in the workpiece loading and unloading area of the workbench (the workbench is equipped with a groove that can accommodate the bulge on the steel back). The workpiece enters the magnetic area with the rotation of the worktable and is sucked. After rough grinding, fine grinding, and then manual unloading in the demagnetization area, the process can be carried out continuously

The1year

The1year

Brake pad multifunctional disc li

Brake pad multifunctional disc li

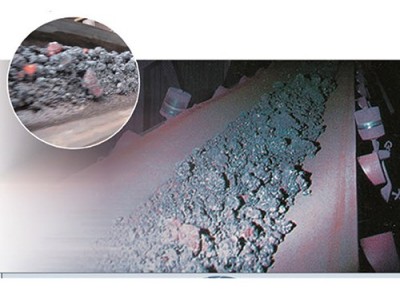

Surface cleaning machine

Surface cleaning machine

Automobile brake pad grooving and

Automobile brake pad grooving and

European powder spraying line dry

European powder spraying line dry

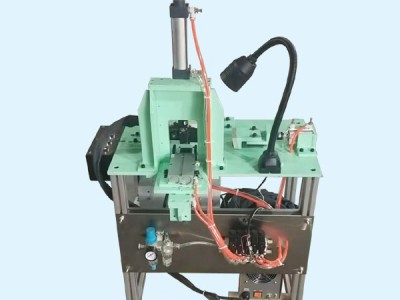

Brake pad steel back glue sprayin

Brake pad steel back glue sprayin