(1) The glue spraying process is equipped with an independent conveyor belt, and the glue spraying conveying speed is adjusted according to the glue spraying process;

(2) Dust remover shall be set to treat the smoke I dust generated in the process of glue spraying synchronously to ensure that it does not pollute the environment;

(3) The glue spraying transition device is set, and the glue spraying process is in contact with the front of the steel back at the apex of the detachable point support mechanism. The adhesive on this point is easy to be cleaned up in the surface treatment process of the subsequent process, which fundamentally solves the influence of the adhesive on the surface treatment of the product caused by the adhesive on the surface of the conveyor belt;

(4) Each detachable point support mechanism on the glue spraying transition device exists independently. When some parts are damaged and need to be replaced, only the damaged parts can be removed and replaced without affecting the normal use of other parts;

(5) Flexibly adjust the height and quantity of removable point support mechanism according to the size of steel back;

(6) A glue spraying recovery device is set, which can timely and efficiently recycle the excess glue spraying;

(7) Through the more simple and efficient automatic equipment, the processing efficiency is improved, the maintenance is convenient, and the production cost of the enterprise is saved.

The1year

The1year

Row flow electrostatic spraying p

Row flow electrostatic spraying p

Brake pad steel back deburring ma

Brake pad steel back deburring ma

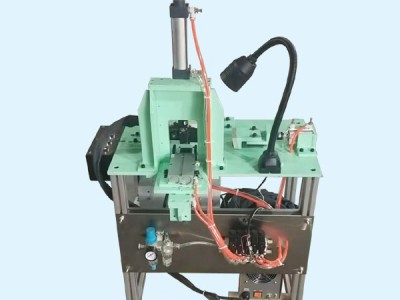

Brake pad gluing machine

Brake pad gluing machine

Bus brake pad spraying production

Bus brake pad spraying production

Bus spot welder

Bus spot welder

Surface cleaning machine

Surface cleaning machine