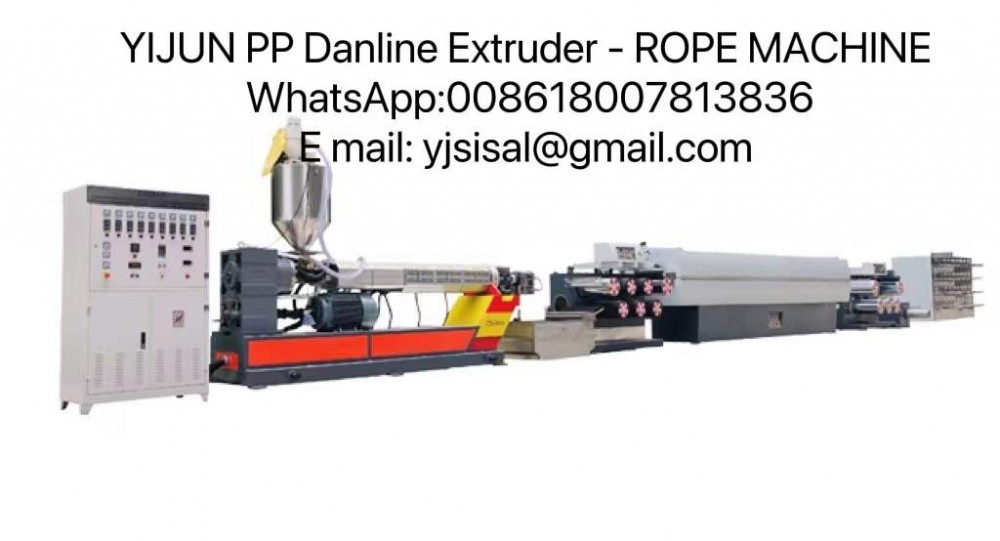

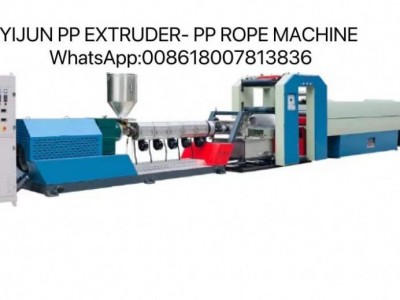

PP Danline Extruder rope machine

PP Danline Extruder

Technical data

Item | HDYSD-70*33 | HDYSD-80*33 | HDYSD-90*33 |

Screw Diameter | 70mm | 80mm | 90mm |

Fiber Diameter | 1000D-3500D | 1000D-3500D | 1000D-3500D |

Fiber Type | PP danline Yarn For Making Rope or Net | ||

Spinning holes | 72 | 96 | 108 |

Ratio of L/D | 33 | 33 | 33 |

Rotation Speed of Screw | 20-90r/min | 20-90r/min | 20-90r/min |

Drawing Ratio | 4-10 | 4-10 | 4-10 |

Cooling Mode | Water Cooling | Water Cooling | Water Cooling |

Stretching Hot oven | 6000*600*1000mm | 6000*600*1000mm | 6000*600*1000mm |

Power Consumption | 110KW/80KW | 120KW/90KW | 120KW/90KW |

Max Output capacity | 1200KG/24H | 2000KG/24H | 3000KG/24H |

Machine Weight | 11 Tons | 12 Tons | 12 Tons |

Machine Dimension(L*W*H) | 25*2.3*1.85M | 27*2.3*1.85M | 27*2.3*1.85M |

PP Danline Extruder

PP danline extruder machine

This machine can produce different size of pp danline yarn for marine and fishery usage.

The yarn is for making plastic rope, fishing rope, mooring rope, etc.

Performance & Advantages:

· Screw and barrel are made of nitriding steel 38CrMoAl with special hardening, has good corrosion resistance and wear resistance, longer life.

· AC Inverter & Motor can synchronize the entire extruder.

· Latest technology used for force the melt into the die very effectively.

· Easy control and adjust system, make production more easy and fast.

· Strong material and fine processing of machine, good quality electric parts for long time high efficient working.

· Responsible after sale service, help client install the machine, train using the machine step by step.

The1year

The1year

YIJUN 721B Ring Twister-2

YIJUN 721B Ring Twister-2

PET Monofilament Extruder

PET Monofilament Extruder

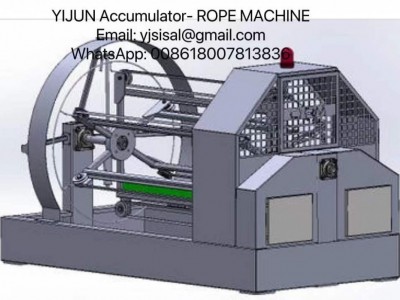

YIJUN Accumulator Rope nachine

YIJUN Accumulator Rope nachine

YIJUN M 55 Rope Machine

YIJUN M 55 Rope Machine

YIJUN 723 Ring Twister

YIJUN 723 Ring Twister

PP Raffia Extruder

PP Raffia Extruder

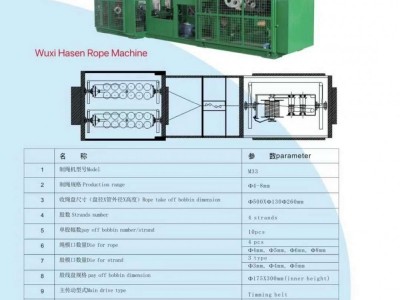

YIJUN M33 Rope Machine

YIJUN M33 Rope Machine

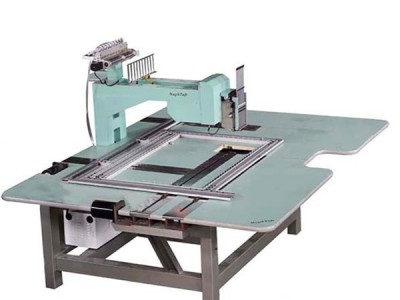

YIJUN multi-heads Spool Winder

YIJUN multi-heads Spool Winder