Deliver:In 3 days

1. product description:

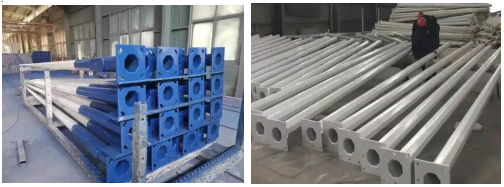

Monitoring poles are also called camera light poles. They are generally divided into Y-type, T-type, and R-type. Specific specifications can be customized and processed according to customer requirements. The single monitor pole is a commonly used specification. It is a high-quality steel plate that is processed into an octagonal shape by a large bending machine. Or hexagonal, or assembled and welded from rectangular square tubes. The surface is hot-dip galvanized for anti-corrosion treatment and the outer surface is spray-coated. It is suitable for urban roads, expressways, viaduct intersections or T-intersections.

2. Technical Description:

(1) Welding process

The entire rod body should be free of cracks, missing welds, continuous pores, undercuts, etc., and the welds should be smooth and flat without any undulations or welding defects. A welding flaw detection report must be provided.

(2) Electrical door

a. The electrical door is plasma cut.

b. The appliance door and the lamp body are integrated, and there is no boss welding at the door opening, so the structure has high strength.

c. Have reasonable operating space and electrical installation accessories inside the door.

d. The gap between the door and the rod should not exceed 1 mm, and it should have good waterproof performance.

e. It has a special fastening system with good anti-theft performance, and its fixing bolts are opened using non-universal special tools.

f. Electrical appliance doors should have high interchangeability, reasonable operating space inside the door, and 3% of electrical appliance door accessories should be provided

g. Weld an M8×30 bolt firmly on the lower left side of the light pole working door and hot-dip galvanize it together with the light pole to connect the PE cable.

(3) Hot dip galvanizing process

The internal and external surfaces should be treated with hot-dip pickling and corrosion treatment. The thickness ≥75um should comply with the GB-/T13912-92 standard. The design service life should be no less than 30 years. The galvanized surface should be smooth and beautiful, with basically the same color. It should not be damaged after the hammer test. The skin does not peel off. Provide galvanizing test report.

3. Packaging & Shipping: