Min quantity:1Piece

1.Brief Introduction:

HOW IS FISH FEED MADE BY OUR fish feed machine?

(1) High-quality ingredients (fish meal, cereals, vegetable proteins …) are selected and ground according to the specific nutritional and pellets size requirements of the aquatic animals and various fish request.

(2)The particle quantity of fish feed raw material is a key factor for premium granulates production: therefore the grinding step is an important unit operation. The powder is then mixed with minor ingredients such as vitamins, mineral premixes… prior to the preconditioning out to the fish extruder directly.

(3) Next, the heart of the process, extrusion cooking is done in three stages in the fish feed machine: preconditioning, extrusion cooking and die texturing/ shaping. Twin-screw extrusion-cooking uses its perfect mixing ability and parameters control such as shear, temperature, residence time to reach the highest physical and nutritional standards. Through direct steam injection, venting device and efficient barrel cooling, adjustable screw speed, screw configuration, shear and temperature conditions are perfectly controlled; this leads to optimized functional and nutritional pellet properties such as the bulk density, calibration, cooking degree, best ratio proteins- lipids, etc

(4) Fish feed Pellets can then be oil coated and possible additives and are cooled down to complete the fish feed processing.

2.Capacity:100-500kg/h

3. Voltage in China:

Threephases:380V/50Hz,Singlephase:220V/50Hz,wecanmakeitaccordingtocustomers' localvoltageaccordingtodifferentcountries.

4. Machines Materials:

Allthemachinesaremadeofstainlesssteel.

5. Technical Parameter:

Model | Installedpower | Consumption | Output | Dimension |

TSE65-P | 70kw | 40kw/h | 100-150kg/h | 22000*1200*2200mm |

TSE70-P | 90kw | 50kw/h | 200-240kg/h | 25000*1500*2200mm |

TSE85-P | 120kw | 100kw/h | 400-500kg/h | 30000*3500*4300mm |

TSE90-P | 135kw | 100kw/h | 800-1200kg/h | 30000*3500*4300mm |

TSE95-P | 150kw | 130kg/h | 2000-3000kg/h | 33000*3500*4300mm |

6.Flow chart:

Mixer---Screw Conveyor---Twin- screw extruder--- Air conveyor---Dryer ---Flavoring line---Cooling machine

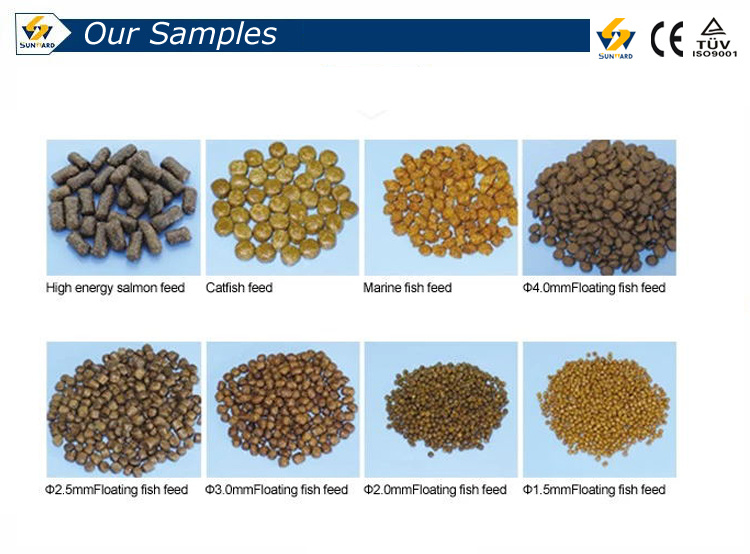

7.Samplesfor your reference:

floating fish food processing making extruder adopts cornflour,wheatflourlow-temperaturesoyaflakesandmealwheatgrainasrawmaterials.floating fish food processing linecanproducedifferentshapes of foodforcattle,sheep,dog,fishorcat, etc.

Main equipment

Mixer

Installed Power: 4kw

Consumption:3kw/h

Output: 30kg/batch-40kg/batch

Mixing Time:(2minutes-3minutes)/batch

Size: 1030*920*1350mm

Function: raw material with water, liquid chemical additive mix together fully.

Feature:

1. This part that contacts mixer to material adopts the stainless steel material.

2. The discharge hole adopts the new handle-opened design, good seal

3. The motor is a Chinese famous brand

Twin-Screw extruder

Installed Power: 53kw

Consumption:37kw/h

Output: 200kg/h-250kg/h

Size: 2600*870*1950mm

Features:

1. The main extruder adopts frequency speed controlling with high automation and stableper-formation.

2. The screws are made of the alloy steel and special craft, durable usage, high pressure,the screw life is longer. Adopting the building block structure and combining willinglyaccording to the different demand.

3. The forced lubrication system can guarantee the equipment transmission life longer.

4. The auto-temperature control system makes the temperature control more direct viewingand the parameter more precise.

5. Self-cleaning, when stopping, it can be cleaned without disassembling.

Multi-layer electrical dryer

Installed Power45kw

Consumption: 30kw/h

Output:200kg/h-300kg/h

Size: 5200*1300*2200mm

Function: Baking and drying the food. All kinds of inflating food, pet food, TVP food, peanut, nut, chew nut can be dried.

Features :

1. The dryer has a compact structure, small occupying,large drying area, small surface area, slight radiating heat, and high thermal efficiency.

2. The belt and the heat preservation use stainless steel; it is suitable for the food industry.

3. The running speed of the belt net can be controlled (frequency)

4. The temperature can be controlled willfully and designed according to the need.

5. Material touching the food is stainless steel, the bracket is ironwith paint. The motor is a Chinese famous brand, Switchboard operation.

Cooling machine

Installed Power: 1kw

Output: According to Extruder

Size:5000*700*1100mm

Feature:

1. This material that contacts food adopts the stainless steel material.

2.The air from the fan cooling the rice going through the conveyor belt.

3. The motor is a Chinese famous brand

Doubleroller flavoring machine

Installed Power:0.75kw

Consumption Power:0.5kw/h

Dimension:2350*870*1780mm

Function: it is usedto seasoning products with flavoring powder and liquid.

Company information

1. Introduction of our company

Our factory was founded in 2009 and our company is an industry and trade integrated enterprise. The company is committed to research and develop extrusion machinery and related ancillary equipment. It is covering mainly machinery and equipment for corn meal milling system, corn flakes/breakfast cereal system, baby food system, corn puff snacks system, pellets system, artificial rice system, soy nuggets system, as well as pet food/fish food system. As the owning import and export right, machines are exported to more and more countries directly by ourselves. Which include Asia, America, Africa, Europe, etc. Besides, our machines are welcome in the countries. So until now, there are not only direct customers, but also some long term cooperation agents.

2. about us

1. Testing Machine before package.

2. Packaging: inside is covered in plastic film, outside is a wooden case.

3. Shipping: 15-35 working days after receiving the deposit.

4. The pictures of our packaging logistics for your reference.

Our Services

-- Before sale service

1. Provide free consultation of the equipment.

2. Provide the standard device and the flow chart.

3. According to the clients' special requirement, offering a reasonable plan and free design helping to select the equipment.

--Services during the sales:

1. Help client design the factory and offering professional advice, free engineering drawing for the factory layout

2.Welcome to visit our factory or the domestic clients' factory.

3. Inspect the machine before leaving the factory.

--After-sale services:

1. Oversea install and debug the equipment.

2. Train the first-line operator.

3. Provide the basic formula.

4. Operation/ Service/ Maintenance Manual: Provided In English.

5. 1-2 engineers will be arranged for customer

If you have any interests in our machines, please don't hesitate to contact us.