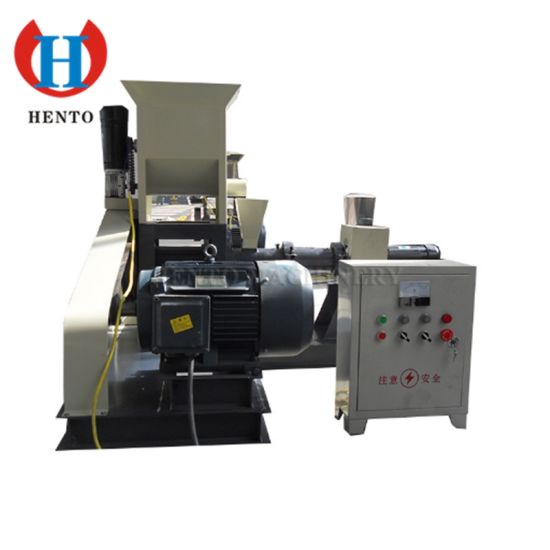

1.Machine introduction of Animal Feed Pellet Machine With Low Price:

1). Wood pellet machine is mainly used to make the biofuel pellets or animal pellets from wood, straw, cotton stalk, rice husk, peanut shell, bamboo, empty fruit branch, pulverized coal and waste paper, etc.

2). The final pellets are of high density, high fuel value, low moisture and low ash content.

3). Wood pellet machine is energy saving machine which can recycle and reuse the agriculture wastes to protect environment.

4). The outlet pellets can be 4-30mm size for option and the pellets can be used for fireplace, animal feed, burning for stove, etc.

5). The wood pellet machine can be used in electric industry, fertilizer industry, animal feed industry, etc.

Wood pellet machines are optional:

Small sawdust pellet machine:

1). Structure: This series of wood pellet machines are consist of Electric motor/Diesel Engine, Gear Box, Axis, Flat Die, Roller, Feeding room, Cutting blade, Outlet.

2). Working principle: This series pellet machine uses the diesel engine or electric motor as power. The gears derive the spindle and die. The raw materials are forced out of the die holes by the squeezing action of the die and roller. Then the high quality pellets are produced. The length of the pellets can be controlled by adjusting the position of the tool bit.

Flat Die Wood Pellet Making Machine:

1). Simple structure, easy operation, stable working and can continuously working.

2). The outlet pellet from these wood pellet machine is of high density, high combustion value, low moisture, low ash, etc.

3). The gearbox adopt high precision gear transmission and four groups of gears docking.

4). Automatic lubrication system for bearings and rollers. When the machine's working, the oil pump is working too. On the condition of automatic lubrication system, the using life of main shaft and bearings will be greatly increased.

5). The mold and rollers are made from hard material of alloy steel. Through thermal treatment, their hardness can be up to 50, which greatly increase the life of the wood pellet machine.

2.Technical parameters of Animal Feed Pellet Machine With Low Price:

Model | Power | Capacity | Dimension (CM) | Weight (KG) |

HT-PKJ350 | 30KW | 300-500 KG/H | 165*70*130 | 1000 |

HT-PKJ450 | 37KW | 500-700 KG/H | 130*70*150 | 1450 |

HT-PKJ550 | 45KW | 800-1000 KG/H | 140*75*160 | 2000 |

HT-PKJ800 | 90KW | 1500-2000 KG/H | 190*100*200 | 3900 |

HT-PKJ1000 | 110KW | 2000-3000 KG/H | 210*115*205 | 4800 |

3.Ring Die Wood Pellet Making Machine:

The new product HTORP series "double vertical ring-die pellet mill" are research, Design, Produced by ourselves, With alone shape, more reasonable structure and stability,Professional for Wood, Rice husk, Peanut shell, Bamboo and Palm fiber etc.

1) Gearbox: Continue the HENTO series New generation gearbox, Driving with high-precision gears, Auto-matic Lubricant pump system keep the gearbox working stability and warranty period. 2) Vertical motor: the most characteristic is mounting hole with output shaft as the center, equidistant distribution around, More powerful and stability of machine working. 3) Blower system: Located in one side of work bin, Free control the working time, The main function is dedusting and discharge steam. 4) Working parts: Ring-die and rollers materials are alloy steel, Heat treatment made by ourselves, Hardness more than 52, In this hardness can assure the pelleting quality and warranty time, Working manner is from inside to outside press, Centrifugal force and extrusion pressure together,Produced more capacity, At the same time assure hardness and density, The special design is 4 to 8 rollers working, Increase press rate then increase capacity, Ring-die is "vertical double-deck" structure, It can use one mould with same hole size for working life increased, Moreover it can use one mould with different hole size for saving the money for another size mould.

Model | Power | Capacity | Pellet size | Weight | Dimension |

| HT-RP450 | 55 kw | 0.8-1.2 ton/h | 6-12 mm | 2800 kg | 1.4x0.75x1.55 m |

| HT-RP550 | 90 kw | 1.5-2 ton/h | 6-12 mm | 4500 kg | 1.9x0.95x1.8 m |

| HT-RP800 | 132 kw | 2-3 ton/h | 6-12 mm | 7000 kg | 2.5x1.35x2.1 m |

| HT-RP1000 | 160 kw | 3-4 ton/h | 6-12 mm | 8500 kg | 2.65x1.45x2.1 m |

4.Contact Information

If you need further information, please contact us freely, we will do our best to cooperate with you.

The website of our company:

zzhento.en.made-in-china.com

zzhento.en.made-in-china.com