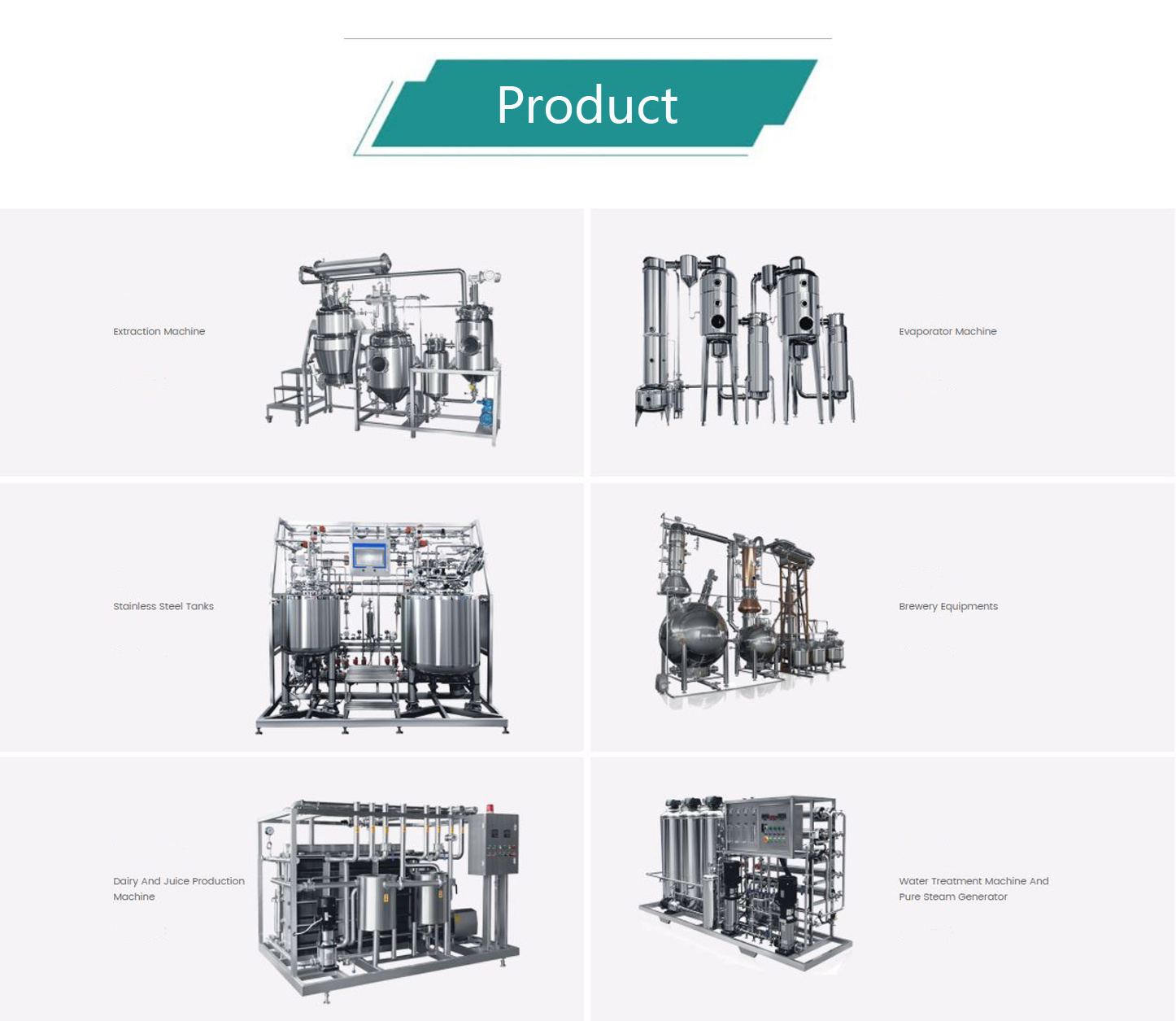

Double Water bath sterilizer directly injects steam to make the water in the hot water tank rise to a predetermined temperature, and then injects it into the process tank. At the same time, the process water in the boiler is continuously recycled, and the water is heated and sterilized through the water vapor mixer. Therefore, the sterilization time is shortened and the work efficiency is improved. The sterilization process water can be recycled, saving energy, time, manpower and material consumption, reducing production costs.

Double Water Bath Sterilization Pot Equipment features:

Water bath sterilization pot can be divided into: double water bath sterilization pot, Double pot parallel water bath sterilization pot, three pot parallel water bath sterilization pot.

Double layer water bath sterilizer

1. Save energy. The working medium used in the sterilization process can be recycled, which saves energy, time, manpower and material consumption, and reduces the production cost.

2. High temperature short-time sterilization uses double tank hot water circulation for sterilization. The water in the hot water tank is heated to the temperature required for sterilization in advance, so as to shorten the sterilization time and improve the work efficiency.

3. Uniform water flow exchange mode, uniform temperature, no dead angle, using international advanced technology, using hot water circulation, immersion sterilization, in the sterilization process, the circulating water in the sterilization tank is continuously switched up and down, ensuring that the sterilization tank from heating, heat preservation to cooling, the heat distribution at any point is uniform, effectively eliminating the dead angle phenomenon in the sterilization process, Make the shelf life of products more stable and long.

4. The temperature in the sterilization tank is always stable in all stages of the sterilization process, which ensures the qualified rate of F value.

5. Automatic control system. The whole sterilization process is controlled by computer PLC and completed at one time without manual operation. It adopts chart panel and touch control by screen. All time periods are controlled by analog sensors and automatic valves. It can switch from single sterilization process to multi-stage sterilization process. The pressure and temperature are displayed digitally, and various pressure and temperature modes suitable for any product can be programmed in advance and input into the computer.

6. The function of measuring F value. Each sterilizer produced by dingtaisheng company can be equipped with f-value measuring instrument, which has the function of measuring value. The f-value software calculates the f-value every 3 seconds. All sterilization data, including sterilization conditions, F value, time temperature curve and time pressure curve, can be saved or printed after being processed by data processing software for production management.

7. The simulated temperature control system can set multi-stage heating mechanism, and set different heating and cooling procedures at any time according to the requirements of different food sterilization conditions. The multi-stage heating sterilization method can be used to minimize the heat of food, so as to preserve its color, fragrance and taste perfectly, So that each kind of food can be in the best condition for conditioning and sterilization. The sterilization temperature is accurate to ± 0.3 ºC, which can avoid over cooking or incomplete sterilization.

8. 100 sterilization formulas can be stored in the computer for selection.

| model | Barrel length(mm) | Capacity(kg) | Effective volume(m3) | Internal volume(m3) | power(kw) |

| AN-700 | 1200 | 100-150 | 0.24 | 0.46 | 30 |

| AN-800 | 1500 | 200-280 | 0.43 | 0.75 | 36 |

| AN-900 | 1800 | 350-400 | 0.64 | 1.14 | 45 |

| AN-1000 | 2400 | 500-550 | 0.95 | 1.72 | 60 |

| AN-1200 | 2400 | 600-750 | 1.04 | 2.71 | 90 |

| AN-T1200 | 3600 | 800-1000 | 2.5 | 4.5 | 90 |