Water treatment → EDI,ultraviolet(alternative) → water tank → Ozone generator,pump(alternative) → homogenizer emulsifier → material tank → automatic filling and capping machine → automatic labeling machine → ink printer

Chemical machinery equipment chemical machinery

Chemical machinery equipment chemical machineryProduct Description

Facial lotion, facial cream vacuum emulsifying mixer for high viscosity from China supplier means when the materials are under the vacuum condition, it makes use of the high shear emulsifier to distribute one or several to another continuous phase rapidly and evenly. The materials will be processed in the narrow space between stator and rotor by strong energy of motion produced by the machine effect.

By the operation of hydraulic sheraing, centrifugal extruding, impacting, breaking and turbulence for over 199 thousand times per minute, the materials will be disperesed and emulsifed instantly and evenly. After reciprocating circulation at high frequency, the fine finished products of stable and high quality without bubbles will be achieved.

What isvacuum mixer homogenizer?

These machines are generally called mixer homogenizers or vacuum mixer emulsifiers. They are mostly used for batch production of ointments , creams, suspensions, gels, toothpaste and similar products, with operations that include ingredient loading , mixing and blending with heating and cooling steps, as well as any necessary deaeration of the mixer, according to pre-set operating standards.

What isvacuum emulsification plant made of?

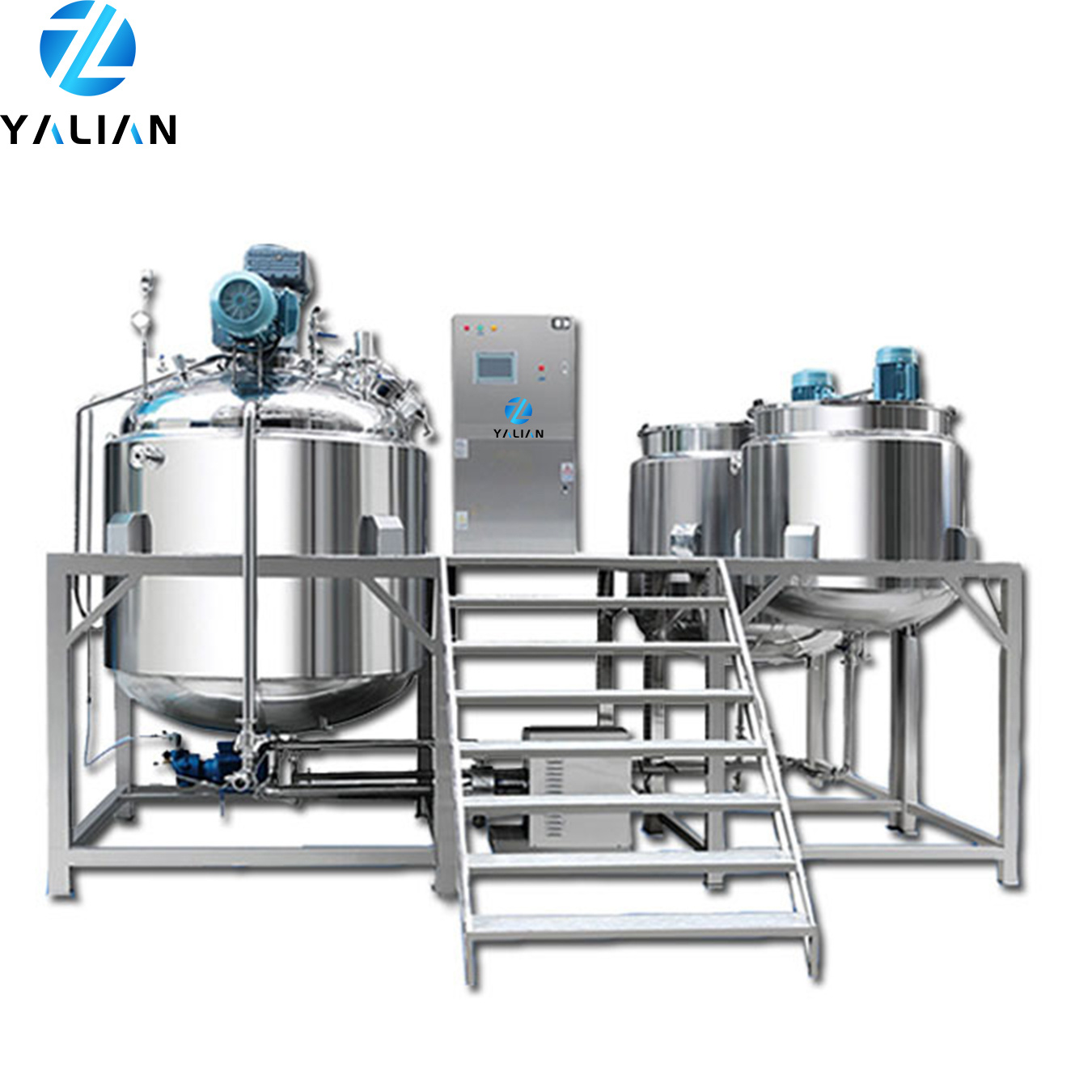

The vacuum emulsification equipment is generally made of main emulsification blender, oil phase mixer, water phase mixer, vacuum system, hydraulic lifting system(Option), tilting system for the main emulsifying mixer, heating and cooling system, temperature control system, electrical control panel etc.

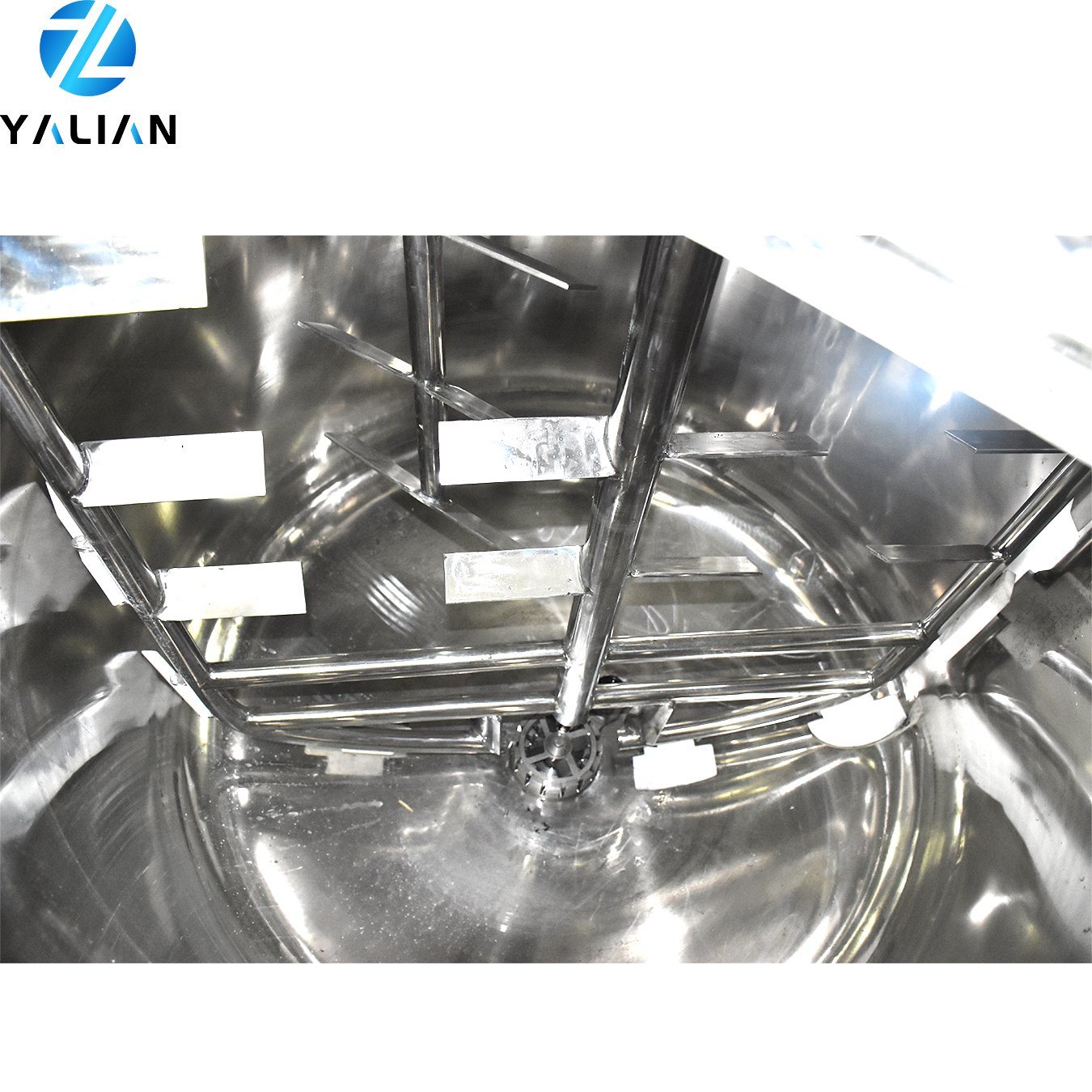

The main emulsification mixer consists of a high speed rotor stator homogenizer and counter-rotating centre agitator and wall scraper. The homogenizer, centre agitator and wall scraper are all mounted from the top of the cover.

The oil and water phase mixers have exactly the same construction. There's a high speed disperser mounted from the top of the cover which helps dissolve the ingredients. Some customers will omit the oil and water phase mixers and keep the main emulsification machine only.

The emulsifying effect is more prominent for materials ofhigh base viscosity and high solid content.

How To Choose

No. | Model | Volume(L) | Blending power(KW) | Blending rotation(r/min) | Homogenizing power(KW) | Homogenizing rotation speed (r/min) | Heating method |

| 1 | YMC-D-200 | 200 | 1.5 | 0~65 | 3 | 3000 | steamorelectric heating can be selected |

| 2 | YMC-D-500 | 500 | 3 | 0~65 | 4 | 3000 | |

| 3 | YMC-D-1000 | 1000 | 4 | 0~65 | 7.5 | 3000 | |

| 4 | YMC-D-1500 | 1500 | 4-5.5 | 0~65 | 11 | 3000 | |

| 5 | YMC-D-2000 | 2000 | 5.5 | 0~65 | 15 | 3000 | |

| 6 | YMC-D-3000 | 3000 | 7.5 | 0~65 | 22 | 3000 | |

| 7 | YMC-D-5000 | 5000 | 11 | 0~65 | 32 | 3000 |

Engineer :

Engineer :

The product of vacuum emulsifying mixer machine mainly applied in such industries as daily chemical care products, biopharmacutical industry, food industry, paint and ink ,nanometer materials, petrochemical Industry, printing and dyeing auxiliaries, pulp & paper, pesticide, ferilizer, plastic & rubber, electronic and electronics, fine chemical industry, etc.

Shampoo / Lotion/ Hand wash / Gel / Body wash , detergent , Ayurveda shampoo mixing and finally production line mixing blending and storage tanks with agitator of liquid detergents including Liquid cleanser essence, lotion , shampoo,Hand wash, shower gel and liquid soap than transferring to bottle filling capping labeling machine line for final product pack and ship to market .

Shampoo / Lotion/ Hand wash / Gel / Body wash , detergent , Ayurveda shampoo mixing and finally production line mixing blending and storage tanks with agitator of liquid detergents including Liquid cleanser essence, lotion , shampoo,Hand wash, shower gel and liquid soap than transferring to bottle filling capping labeling machine line for final product pack and ship to market . Company in details

Company in detailsGuangzhou Yalian is a large-scale company specialized in design, manufacturing, installation and commissioning of daily chemical, chemical, food and pharmaceutical machinery, as well as water treatment equipment. With powerful technical strength, complete inspection facilities, unique and advanced technique as well as great varieties of products, the enterprise strictly implements ISO9001 standard management.

RFQ:

RFQ:1.Q: Areyouamanufactureror just atradingcompany?

A: Guangzhou YALIAN CosmeticsMachinery Co. Ltd is one of the top technology-oriented machinery manufacturer in China.

2. Q: I am new in this field , can you recommend the whole production line?

A: We can recommend you the whole production line depends on what products you will make:

(1).If forpaste or cream product, the following machine we will recommend you:

RO water treatment equipment→Vacuum homogenizer→Storage tank→Paste filling machineorHeating mixing filling machine→Capping machine→Labeling machine→Inkjet printer→ Shrink film packing machineetc.,

(2).If forliquid product, the following machine we will recommend you:

RO water treatment equipment→ Blending tank→Storage tank→Liquid filling machine→Capping machine→Labeling machine→Inkjet printer→ Shrink film packing machineetc.,

(3).If forPerfume, the following machine we will recommend you:

RO water treatment equipment→ Perfume making machine→Perfume storage tank→Perfume filling machine→Perfumecrimping machine→Perfume collar machine→Inkjet printer→ Shrink film packing machineetc.,

(4).There areFull automatic production lineandSemi automatic production linefor your option.

3. Q: What is your payment term?

A:We usuallypay by T/T., 40% deposit after sales /confirm/iation, 60%before delivery.

4. Q: What is your delivery day?

A: Our delivery day is about 15-30 days after receive the deposit.