Product Overview

PDC Drill Bit With Extremely Fast Penetration Rates And Very Long Working Life

about PDC Drill Bit

Polycrystalline diamond compact (PDC) bits deliver premium performance and durability for a wide range of standard drilling applications. These matrix- and steel-bodied bits incorporate the latest cutter technology, computational fluid dynamics (CFD), enhanced hydraulics, and various structure geometries to maximize ROP.

Mainly used to drill the roof and side supporting hole, the gas drainage, water infusion, geological exploration hole and grouting hole and so on for the coal mine seam, water conservancy and hydro-power, dam and roadway construction of bolt-mesh support.

Product Description

Polycrystalline diamond compact (PDC) drill bits are made with synthetic diamond cutters in either steel

or matrix body material. PDC drill bits revolutionized the drilling industry with a wide application range

and high rate of penetration (ROP) potential. Unlike roller cones, these polycrystalline diamond compact

(PDC) drill bits are one piece bodies with no moving parts. The fixed-cutters shave away the rock, making

it possible to operate with higher rotation speeds more efficiently in consolidated formations.What Does Polycrystalline Diamond Compact Bit Mean?A polycrystalline diamond compact (PDC) bit is a bit that uses synthetic diamond disks, called "cutters." to

shear its way through rock with an ongoing scraping motion. The PDC bit is particularly suited to drilling

throuah shale formations. which present some specific problems with reaard to borehole instabillitv. such

as borehole narrowing.

Types of PDC Bits1. Matrix Body PDC Bits“Matrix” is a very hard, rather brittle composite material comprising tungsten carbide grains metallurgically bonded with a softer, tougher, metallic binder. Matrix is desirable as a bit material, because its hardness is resistant to abrasion and erosion. lt is capable of withstanding relatively high compressive loads, but, compared with steel, has low resistance to impact loading. Matrix is relatively heterogeneous, because it is a composite material. Because the size and placement of the particles of tungsten carbide it contains vary (by both design and circumstances, its physical properties are slightly less predictable than steel. Matrix-body PDC bits are commonly preferred over steel-body bits for environments in which body erosion is likely to cause a bit to fail. For diamond-impregnated bits, only matrix-body construction can be used.2. Steel Body PDC BitsSteel is the opposite of matrix. It can of withstanding high impact loads, but is softer and lacks protective features. The strength and ductility of steel give steel-bit bodies high impact resistance. Steel bodies are considerably stronger than matrix bodies. A beneficia feature of steel bits is that they can easily be rebuilt a number of times because worn on damaged cutters can be replaced rather easilv. This is a particular advantaae for operators in low-cost drilling environments.

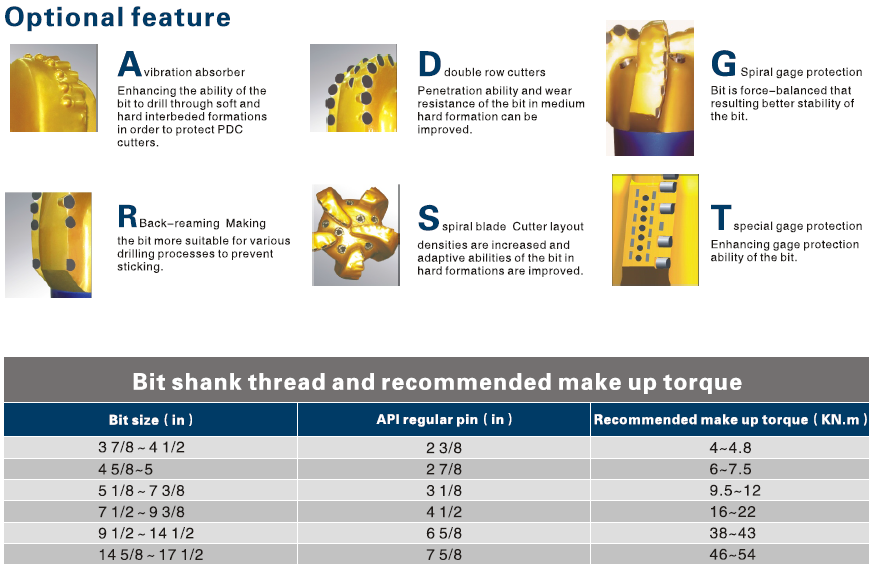

feature

0 Deep blade and medium parabolic configuration design,ensures optimal bottom hole flow pattern and anti-balling. Optimize

the cuttina structure and places hiah auality cutters at different points. increases wear resistance and offensive of the bit.

Anti-whirl design improves ROP and enhances drilling stability. Additional Row Double rows five blades design,maximized enhances

wear resistance and stability of the bit. Deepened Blade Unique deep blade designlessens the torque, increases the footage

capability and rate of penetration of the bit. High Density Cutters High density PDC cutting structure design, ensures efficient

reaming and drilling while extending the application and performance range of casing running operation.

How to choose the right PDC drill bit?

What is the diameter of hole do you want to drill ? Then we can know which item drill bit is suitable you .

What is the layer do you want to drill ? Then we can know which PDC tip is right for you .

SPECIFICATIONS PDC driling drag bits

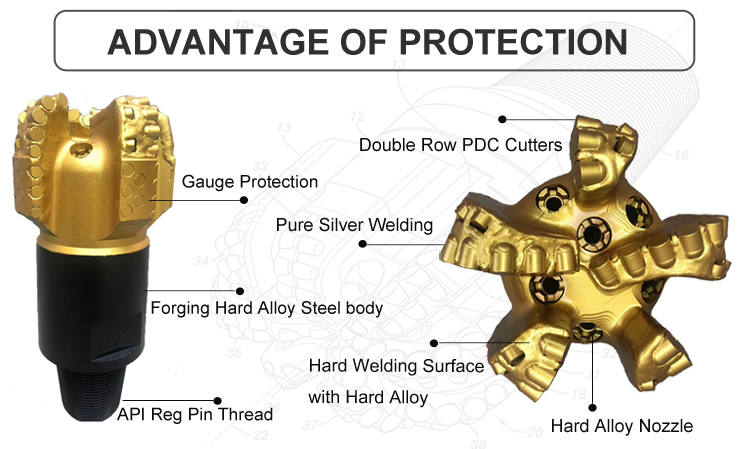

PDC drilling drag bit is made by PDC cutters and steel. It is one of the steel body PDC bit and belong to non core diamond pdc bit. Having the feature of long service life and wear resistance. Widely used in coal mining and water well drilling.

Cutting Structure of this series PDC bit :

1. PDC cutter size 13mm*16mm and 13mm*10mm

2. PDC bit blades number is six

3. The crown part of PDC bit is a long parabolic crown

4. PDC cutter is double row in each blade

5. Each blade has teeth to protect the diameter of the PDC bit

6. The surface of each blade is designed with tungsten carbide welding to enhance the wear resistance of

the blade and improve the service life the PDC bit.

Don’t see the bit you are looking for? Give us a call, we can customize any bit to fit your unique circumstances.

Tag: diamond oil drill bit, well drilling tools, oil well drill bit

1. PDC Matrix Body bit

Type and Features

PDC bit can be customized for oil well,water well, mining, explorer well drilling.

Suitable Formation

Various of hardness rocks or mud except the hardest hardness or ununiform rocks like cobble.

Main Type

Bit Diameters: 5 7/8",6",6 1/2",8 1/2",9 1/2",9 5/8",9 7/8",12 1/4", etc.

Body Type: Matrix or Steel

Cutter Sizes: 5/16"(8mm), 1/2"(13mm), 5/8"(16mm), 3/4"(19mm),etc.

Blades:2~9 Wings

2. PDC Matrix Body Core Bit

Type and Features

PDC core bit can be customized for oil well,water well, mining, explorer well drilling.

Suitable Formation

Various of hardness rocks or mud except the hardest hardness or ununiform rocks like cobble.

Main Type

75/54mm, 94/74mm, 113/89mm, 113/109mm, 153/129mm, 215/105mm, etc.

Don’t see the bit you are looking for? Give us a call, we can customize any bit to fit your unique circumstances.

Our Services

(1)Produce PDC bits and other drilling accessories.

(2)All model drag bits are available,MOQ is only 1 set.Many sizes in stock.OEM,ODM. Export to USA,Europe,Asia,Africa,America and Australia.

(3)Fast production for big orders,delivery by sea,truck,air,express.Works on FOB,CFR,CIF.