Beer brewery

♦♦♦♦♦Beer distribution tanks are also called serving tanks, tax determination tanks or clear beer tanks (=CBTs), bright beer tanks (=BBTs) or maturation/storage or conditioning tanks. These tanks are used for the storage of the beer prior to being served or packaged. Depending on their application the beer serving tanks can be glycol jacketed or can be located in a walk-in cooler. For brewpubs serving is often done by pumping or pressurizing the beer toward the serving location.

brewhouse system one of the main factors that determine beer output, and the saccharification equipment combination is related to the production efficiency and investment scale of saccharification system

Two vessels(American equipment)

1 mash tun and lauter tun , boiler kettle and whirlpool (with heating) :

This kind of combination can saccharify about two batches a day.This kind of equipment can be used in one pot.High utilization of equipment.Equipment investment cost is low.Low productivity.

The brewhouse capacity is one of the main factors that determine beer output, and the brewhouse system equipment combination is related to the production efficiency and investment scale of saccharification system

Two tank of 3 vessels equipment (German type equipment)

Generally,mash tun and boiler are integrated, and the lauter tun + whirlpool kettle is a whole, in which the lauter tun and whirlpool kettle are divided into two layers.The upper layer is the lauter tun , and the lower layer is the whirlpool kettle .

♦♦♦♦♦The brew house system could be included two-vessels brew house, three-vessels brew house and four-vessels brew house. Two-vessels brew house includes mash/lauter tun and kettle/whirlpool tank. Three-vessels includes mash tank, lauter tun and kettle/whirlpool tank. Four-vessels includes mash tank, lauter tun, boiling kettle and whirlpool tank. The capacity is bigger, the vessels is more. It is just in order to reduce the brewing time, improve the working efficiency.

Conical fermentation tank with cooling jacket structure is dished head and cone bottom,with Polyurethane installation and dimple cooling jackets .There is a cooling jacket on tank cone section,columnar part has three cooling jackets.

| Capacity/batch | 100L | 200L | 300L | 500L | 1000L |

| Model | TS-100L | TS-200L | TS-300L | TS-500L | TS-1000L |

| Area | 15M2 | 25M2 | 35M2 | 45M2 | 80M2 |

| Power | 8kw | 12kw | 20kw | 35kw | 35/15kw |

| Frementation cycle | 8~20days | 8~20days | 8~20days | 8~20days | 8~20days |

PRODUCT FEATURES:

1)Desiging tanks and heating system according to craft, mash tank warming≥10ºC/min

2)Energy saving stir structure : large cross-section impeller, 15r/min speed

3)Sieve plate of filter tank includes welding sieve plate and milling sieve plate.

4)Plow knife of filter tank separated to one foot, feet and bow plow knife

5)Wort boiling heat way includes steam jacket, interior heating and exterior heating.

6)Material includes stainless steel 304, 316 and red copper

Fermeners

Material: stainless steel 304, brushed outer shell

*Dimple plate cooling jacket on tank body and conical bottom

*Insulation: polyurethane, thickness: 80mm

*Interior thickness: 3mm

*Exterior thickness: 2mm

*Temperature sensor TP100

*Sidemanhole

*Taper angle 60°

*Inner tank mechanical polishing and out plate surface protection ribbon polished on welds

*1pcs x breathing valve*1pcs x mechanical pressure regulationvalve

*1pcs x sample valve *1pcs x racking arm

*1pcs x pressure gauge *1pcs x CIP spray device

*1pcs x drain outlet bottom *1pcs x solenoid valve

*4 heavy duty legs with leveling pad *Test pressure: 3bar

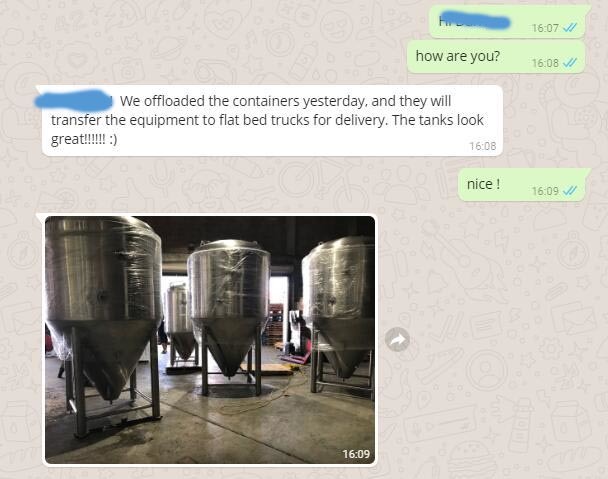

Packing &shipping

1)All tanks will be packed with soft protection material and mounted on steel frame

2)All accessories and spare parts will be packed with soft protect

Company information

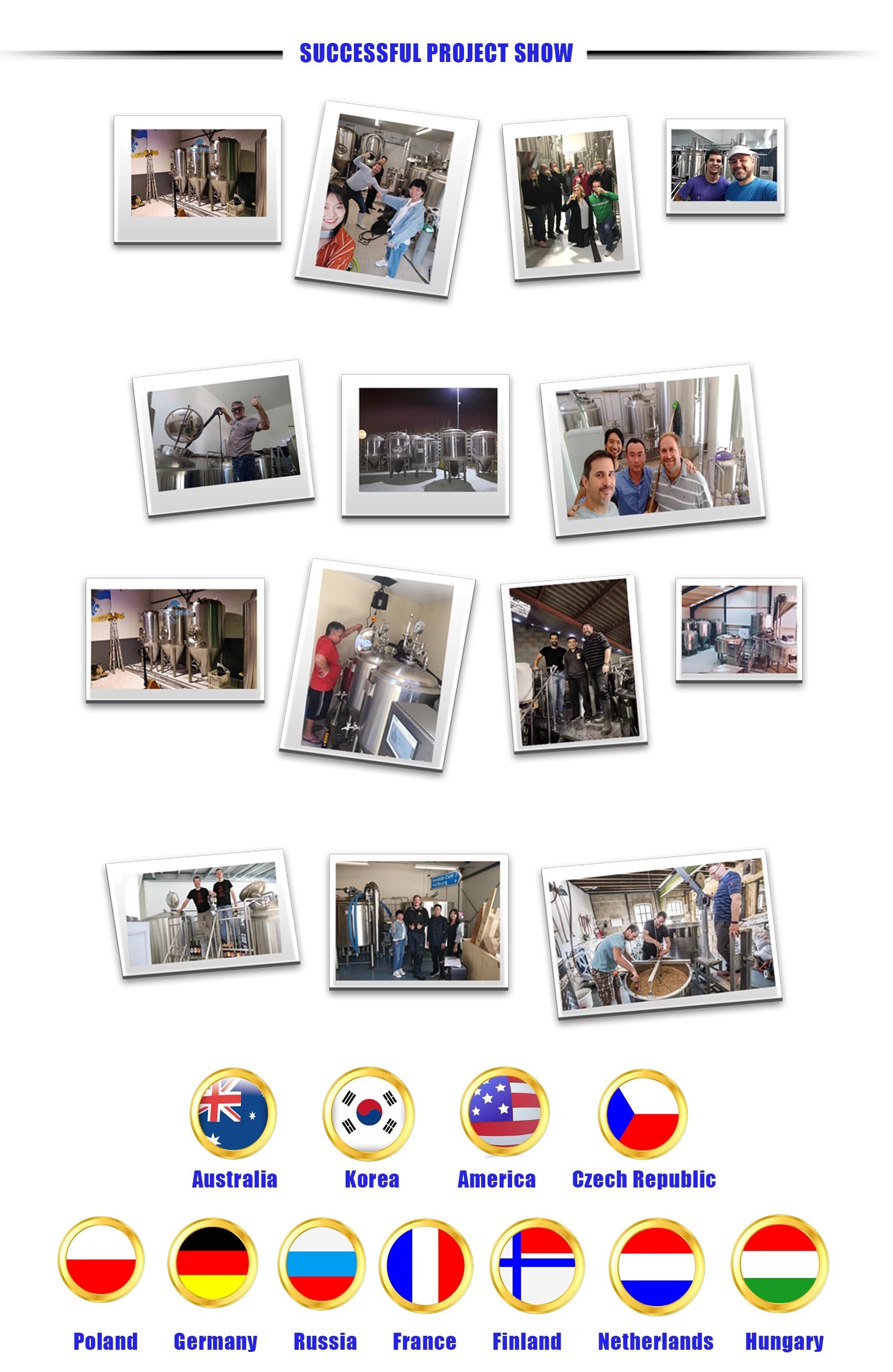

Successful project show

Our products sell all over the China and export to US ,Europ ,Canada ,Russia ,Norway ,Czech, Australia ,Germany , Poland , Brizal , India etc, more than 70countries and areas, and we have abtained many approvals and praise from them.

customerevaluation