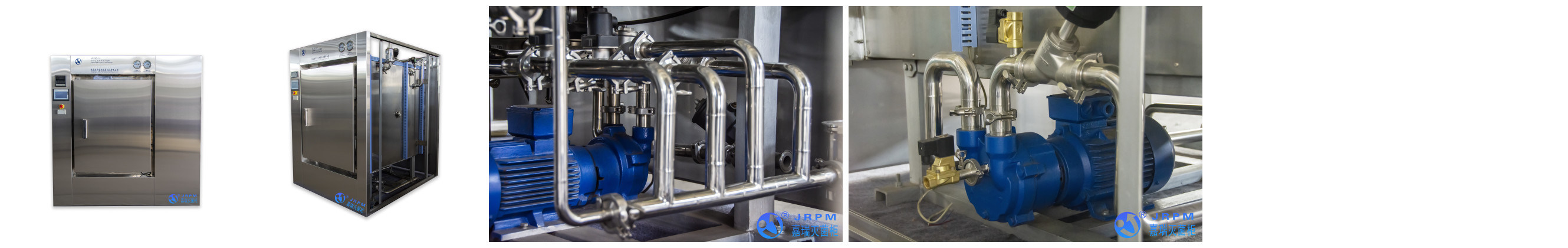

This series of water bath sterilization cabinet uses superheated circulating water as sterilization heating carrier to carry out water drenching sterilization operation on articles. In the whole working process, the superheated water runs in a relatively closed circulation system. The equipment has a series of advantages, such as good temperature uniformity, wide temperature control range (60-134 ºC), and can effectively prevent secondary pollution in the working process. The equipment can be widely used in the pharmaceutical industry for sterilization of glass bottles, retort bottles, plastic bottles, plastic soft bags and other liquids at high and low temperature. It is also suitable for the food industry for sterilization of various sealed packaging, drinking liquid, canned food at high and low temperature

Equipment Parameters:

design pressure :0.245Mpa working pressure : 0.22Mpa

design temperature :139ºC working temperature : 60-134ºC

heat equilibrium :≤±1ºC steam source pressure:0.4-0.6Mpa

Water source pressure:0.1-0.3Mpa

Soft water pressure:0.1-0.2Mpa

STUCTURE&CAPABILITY&CHARACTERISTICS

The inner liner of the main body is made of high quality 304 stainless steel, which is formed by automatic welding. Full stainless steel wire drawing panel decorative housing. With standard GMP verification interface, convenient for users to carry out equipment verification at any time.

The control system adopts Germany Siemens PLC, touch screen (optional computer control), micro printer system.

The control system is stable and the control temperature is accurate. And has perfect data record, print, save.

Pipeline system using the United States ASCO pneumatic valve and Nassim vacuum pump and other optimal configuration.

The equipment can be equipped with automatic in and out of the cabinet system, reduce the labor intensity of workers.

Specification

| Model | Chamber Size L×W×H(MM) | Overall Dimensions L×W×H(MM) | Steam Consumption (KG/CYCLE) | Water Consumption (KG/CYCLE) | Power (KW) | Weight(KG) |

| JR.SG-0.6 | 1050×680×850 | 1330×1650×1920 | 35 | 500 | 2.5 | 1200 |

| JR.SG-1.0 | 1250×750×1100 | 1530×1900×2000 | 45 | 600 | 4.5 | 1500 |

| JR.SG-1.2 | 1500×750×1100 | 1780×1900×2000 | 50 | 800 | 4.5 | 1700 |

| JR.SG-1.5 | 1820×750×1100 | 2100×1900×2000 | 60 | 1000 | 4.5 | 1900 |

| JR.SG-1.8 | 2200×750×1100 | 2480×1900×2000 | 65 | 1200 | 4.5 | 2100 |

| JR.SG-2.0 | 2450×750×1100 | 2730×1900×2000 | 70 | 1300 | 4.5 | 2300 |

| JR.SG-2.5 | 1700×1000×1500 | 2050×2200×2200 | 80 | 1500 | 5.5 | 2800 |

| JR.SG-3.0 | 2000×1000×1500 | 2350×2200×2200 | 100 | 1800 | 5.5 | 3200 |

| JR.SG-4.0 | 2700×1000×1500 | 3050×2200×2200 | 120 | 2200 | 6.5 | 3800 |

| JR.SG-5.0 | 3400×1000×1500 | 3750×2200×2200 | 150 | 2500 | 7.5 | 4500 |

| JR.SG-6.0 | 4000×1000×1500 | 4350×2200×2200 | 180 | 2800 | 7.5 | 5200 |

Poduct standards in line with international Jiarui this tesponsibility To adhere to international standards as a starting paint, The lntroduction of advanced laser cutting machine,Cnc machining centers and other equipment and technology, established products in the high-precision,high-quality and to meet customers' uniqueneeds with international standards of competitiveness.

Certificate

Business cooperation

Packaging & Shipping

After-sales Service Commitment

1, equipment three guarantees of 12 months, lifetime maintenance.

2. Installation and debugging scheme:

3. Service response time:

4 hours response, 24 hours arrangement in place.

5. Maintenance Support:

Provide long-term technical support and service during the service period of the equipment.

6. Guarantee of spare parts

During the service period of the equipment, we promise to supply spare parts at a long-term discount.