Manufactory and Trading Combo Factory Pasteurizer Pipeline Milk Uht Sterilizer

Description

Ultra-high temperature processing (UHT) is a food processing technology that sterilizes liquid food by heating it above 135 °C (275 °F) for 2 to 5 seconds. UHT is commonly used in milk production, fruit juices, cream, soy milk, yogurt, wine, soups, honey.

UHT material packaged in a sterile bag, if not opened, has a typical refrigerant shelf life of six to eighteen months.

UHT pasteurizing Machine is the star product of Shanghai Chase. In the past 14 years, our factory has manufactured dozens of UHT pasteurizing machine for over 20 countries, which won a good reputation. With senior engineers and experienced technicians, shanghai chase is confident to provide our customers superior product with fair price.

Main Features of UHT sterilizing Machine:

- The temperature difference between heating medium and materials is small, which can realize mild heating.

- The heat exchange pipe is made of multi-user, with mirror polishing and less scaling, increasing the lifetime of sterilizer.

- High degree of automation. The whole process from CIP cleaning, sterilization to material sterilization can be automatically

controlled and recorded.

- Accurate and reliable sterilization temperature control: the system influencing the sterilization temperature, such as steam

pressure, flow rate and material flow rate, are strictly controlled automatically.

- The inner wall of the material pipe is polished with advanced automatic welding technology.

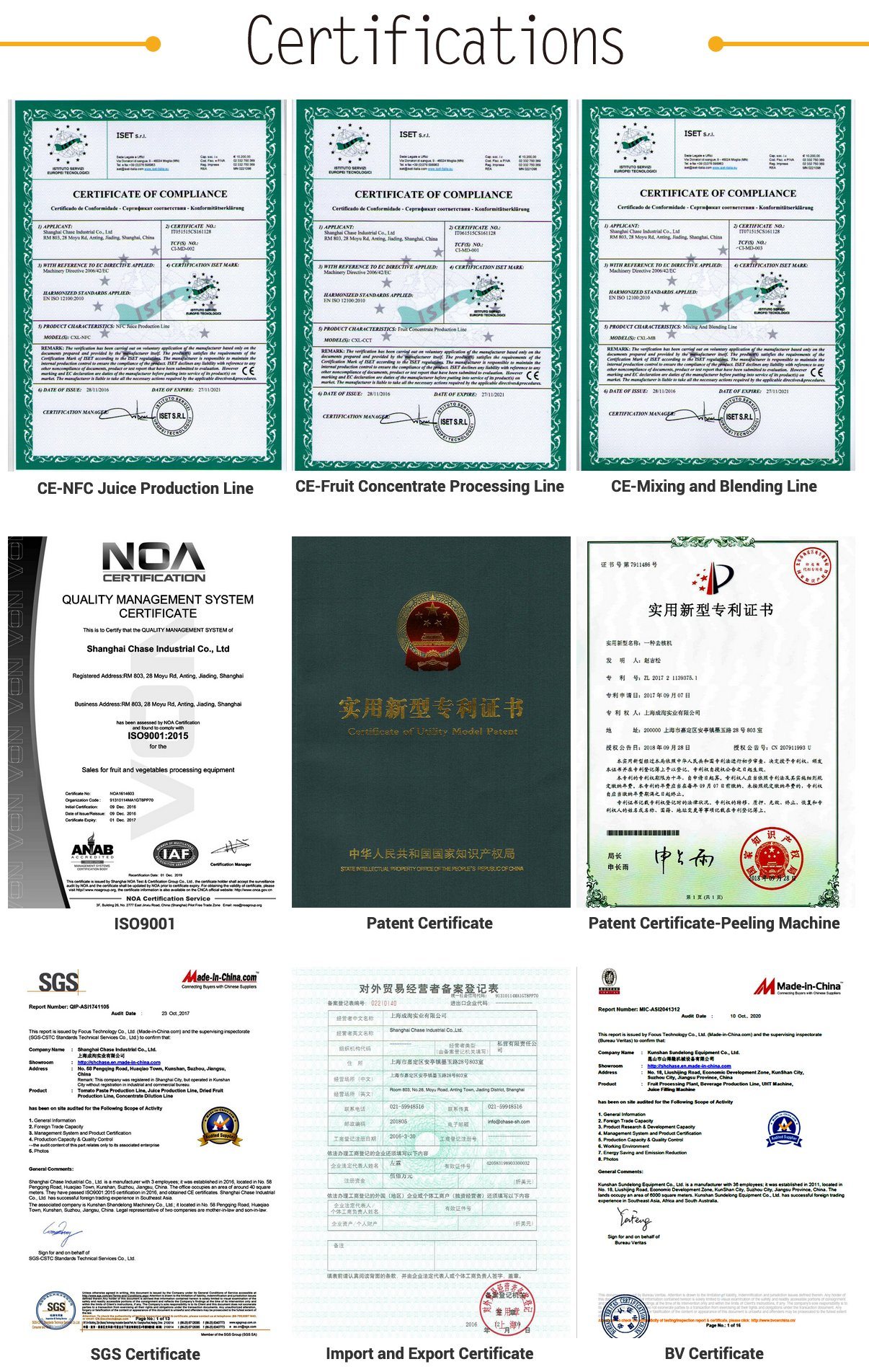

ShanghaiChase Industrial Co., Ltd is founded in 2008, focus on food processing machinery.

We own more than 60 employees with rich industrial experience and advanced mechanical equipment, numbers of CE certific

-ations and invention patents. We have complete service guarantee in equipment manufacturing and after-sale service of fruit

and vegetable processing production machine, Diary processing lines, UHT pasteurizing lines and aseptic filling lines.

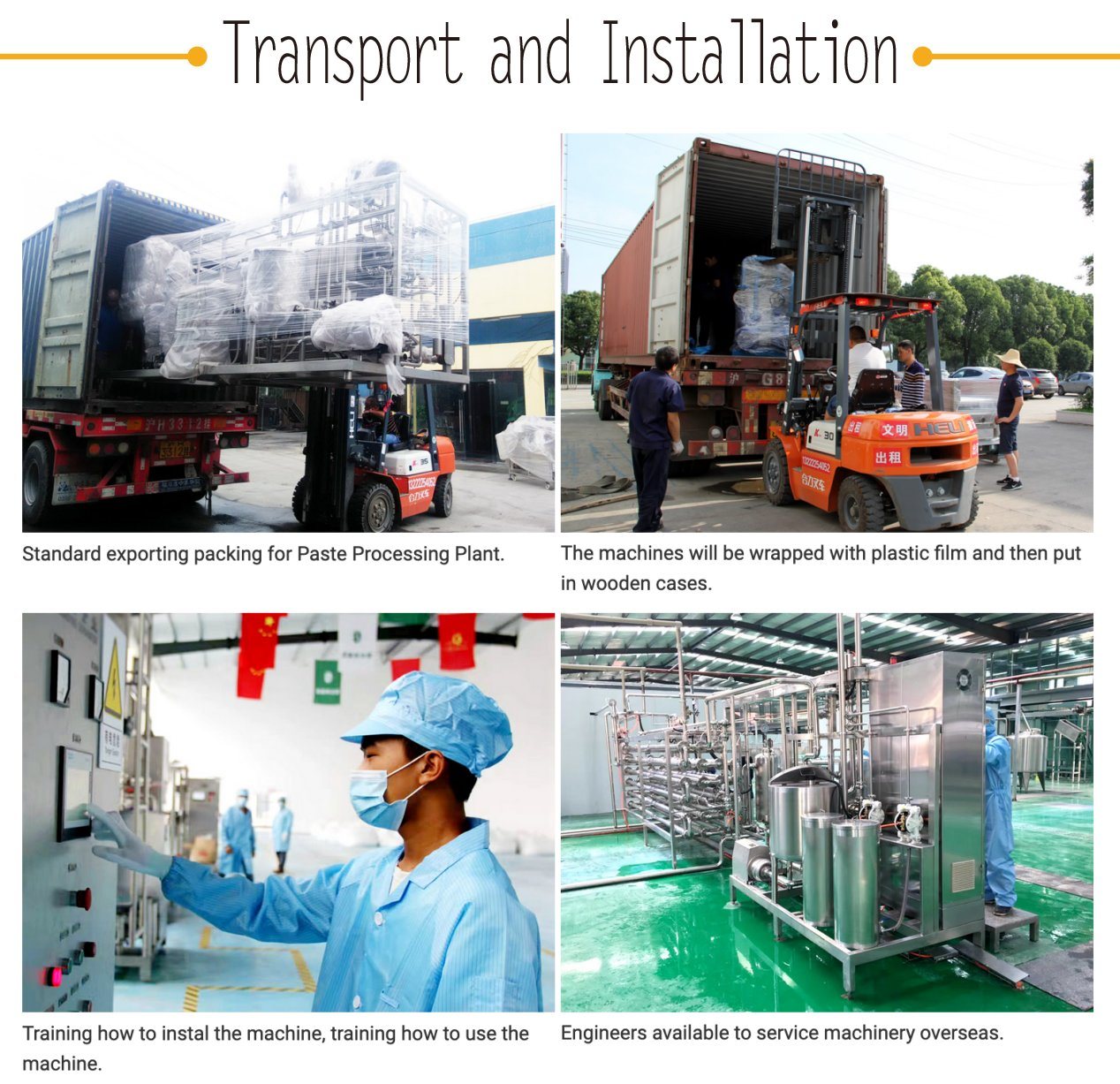

Our workshop covers an area of 8000 square meters, with full production space and equipment which meet

the requirements of production flows. We have experienced mechanical engineers, electrical engineers and

technicians. We design and produce all the important equipment and write PLC control programs by our own

staff to ensure perfect after-sales maintenance. All the equipment is strictly inspected and tested in factory

before delivery, to ensure smooth operation in customer's site.