Marya Steam Air Mixture Sterilizer Kill Germs

Shanghai Marya is a leading EPC supplier for cleanroom system and cleanroom equipment, which including equipmentdesign, material and equipment manufacturing, shipment, installation, validation and after-sales services for pharmaceutical, aerospace, electronics, food processing, cosmetics, new energy and other industries.

Our Products

Super-heated Water Sterilizer

Product Application

This series of products are mainly used for drying, sterilizing and removing-pyrogen the heat resistant articles such as penicillin bottles, aluminum caps, stainless steel metal and glass vessels in the pharmaceutical industry.

Pulsating Vacuum Steam Sterilizer

Product Application

This series of equipment adopt saturated pure steam as the sterilization medium, to do sterilization and drying treatment on clothing, dressings, instruments, medium, glass, etc. The equipment strictly follows the GMP requirements during the process of design, manufacture, test and acceptance, and also online detection and real-time printing of temperature and pressure on the whole process of sterilization to realize that the whole process can be traced back. It is widely used in hospitals, pharmaceutical factory, laboratory, scientific research units and so on to realize disinfectant and sterilization.

Steam Air Mixture Sterilizer

Product Application

This type of equipment uses a mixture of air and steam as heatiing media, and is particularly suitable for sterilization of the less robust packing products.

Equipment strictly follows the GMP requirements for design, manufacture, testing and acceptance, which can realize to temperature and pressure sterilization process of on-line monitoring and real-time print, the whole process can be traced. Typically application is for BFS and pre-filling syringes products terminal sterilization.

Super-heated Water Sterilizer

Product Application

This series of equipment adopt super-heated circulating water as the sterilization medium, to do spray or shower sterilization on Filling product.(Such as ampoule bottles, oral liquid bottles, glass bottles, plastic bottles, soft bags etc.) The equipment strictly follows the GMP requirements during the process of design, manufacture, test and acceptance, and also online detection and real-time printing of temperature and pressure on the whole process of sterilization to realize that the whole process can be traced back. It is widely used in pharmaceutical factory, laboratory, scientific research units and so on to realize disinfectant and sterilization.

ntent="" style="background-color:#bdd7ee;padding:0px 10px;margin:0px;line-height:36px;text-align:left;">about Us

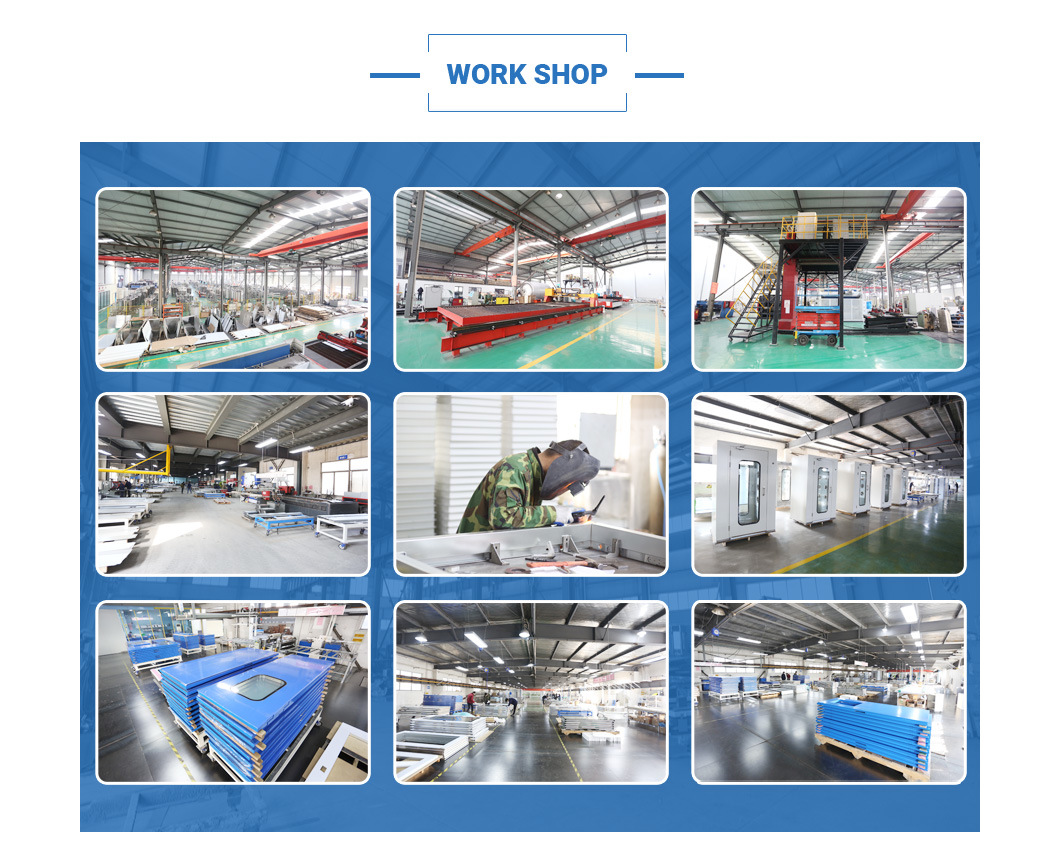

ntent="" style="background-color:#bdd7ee;padding:0px 10px;margin:0px;line-height:36px;text-align:left;">Workshop

ntent="" style="background-color:#bdd7ee;padding:0px 10px;margin:0px;line-height:36px;text-align:left;">Certificate

ntent="" style="background-color:#bdd7ee;padding:0px 10px;margin:0px;line-height:36px;text-align:left;">Project case

ntent="" style="background-color:#bdd7ee;padding:0px 10px;margin:0px;line-height:36px;text-align:left;">Our Customer

ntent="" style="background-color:#bdd7ee;padding:0px 10px;margin:0px;line-height:36px;text-align:left;">Exhibition & Our Team

ntent="" style="background-color:#bdd7ee;padding:0px 10px;margin:0px;line-height:36px;text-align:left;">Packaging & Shipping