feed pellet extruder extrusion equipment lant processing making machine

Our dedication to advancing pet food technology gives our customers specific technological and production advantages:

Introduction ofpet food machine:

1, Materials for dog/cat/fish food:

wheat/ corn flour, fish meal, born powder, animal oil

2,Final food:different shapes and sizes of dog food,cat food,shrimp feed,fish feed,poultry feed

3,Capacity:150kg/h, 250kg/h, 500-600kg/h,800-1500kg/h,2-3t/h,4-6t/h

4,Consumption:Low electricity and labor consumption

5,Design:With flexible design based on the client's demands, we provide turn key project.

6.Pet food machineconfiguration:

Mixer →screw conveyor→Double-screw extruder→Air conveyor→roastingoven→elevator→oil sprayer→flavoring roller→coling conveyor

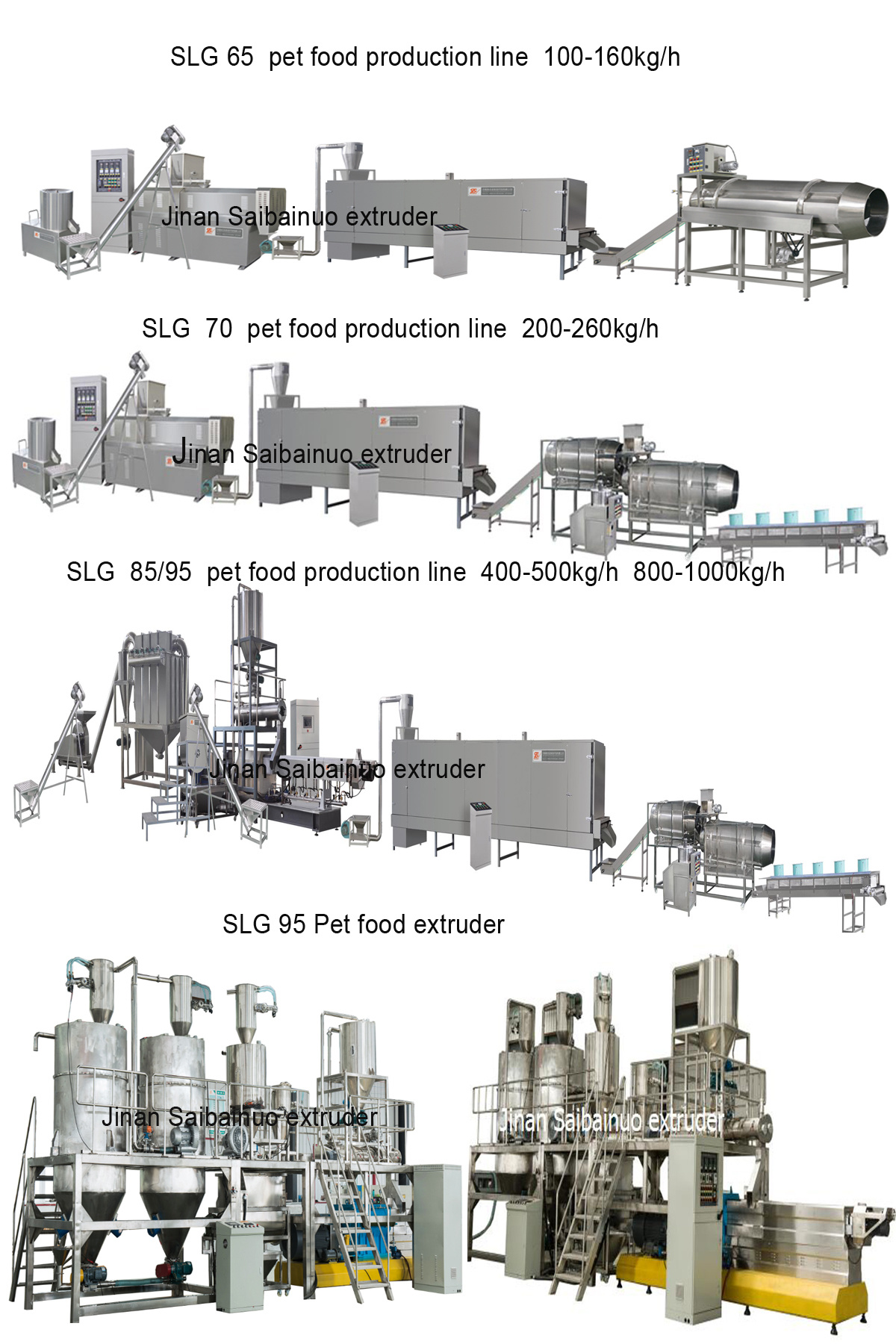

7. Model and parameter of pet food machine:

| Parameter | SLG65-III Pet Food ProcessingLine | SLG70-II Pet Food ProcessingLine | SLG85-II Pet Food ProcessingLine | SLG95 pet food processing line | SLG 120 Pet food processing line | SLG 135 pet food processing line |

| Power | 95KW | 120KW | 140KW | 180kw | 230kw | 280kw |

| Output | 100-160kg/h | 200-260kg/h | 500-600kg/h | 1-2t/h | 2-4t/h | 4-6t/h |

| Dimension | 22× 2× 4 | 24× 2× 4 | 28× 2× 5 | 32× 2× 5 | 35× 2× 5 | 38× 2× 5 |

8. pet food machine picture:

The machine has excellent performance and final product has high quality. Sincerely welcome you come to our factory inspect the machinery.

Stainless steel, this line is with reasonable design and with high automation; The screws are made

by alloy steel, with building block system structure and self-cleaning function.

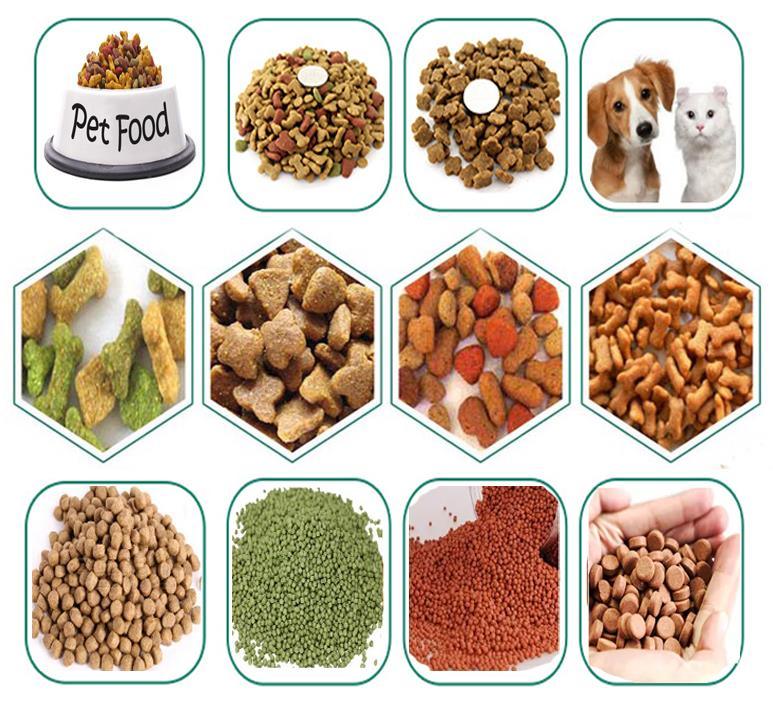

9 Pet food sample:

our automatic line can produce different shapes and sizes of dog food,cat food,fish feed,shrimp feed by changing formula and mould.

Dog food,cat food:

bone shape,fish shape,star shape,round shape,triangle shape,pellet shape and so on

Fish feed:

1mm-14mm floating,slow sinking,sinking fish feed

Detail of extruder:

1. The gearbox is made of bearings and has a shelf life of 10 years.

2. The control system uses ABB electrical components.

3.. 3 minutes cooking time to ensure pre-cooking effect.

4. Deep nitriding process guarantees the life of the screw and barrel.

5.Straight cutting method to ensure smooth surface.

10.Jinan Saibainuo machinery company service:

1) Package &Shipment:Wooden case,shipped by sea.

2) Installation,debugging &Maintenance: Overseas Engineers

| 1.Manufacture | Keep the quality the first. |

| Make more products benifit to customers' need. | |

| 2.Online/Sale service | Supper and solid quality. |

| Fast and punctyal delivery | |

| Standard export package or as customers' need. | |

| 3.After-sale service | Assistance to build factory or your project. |

| Repairing and maintenance if any problem occur in the warranty. | |

| Installation and clerks training. | |

| Spare and wearing parts for free or with big discount. | |

| Any feed back of machines can be told us, and we will try our best to support you. | |

| 4.Other cooperate service | Technology knowledge share. |

| Factory building advising. | |

| Business expansion adbvising |

11.FAQ

MOQ | 1 set |

Supply Ability | 20sets perMonth |

Shipping port | Qingdao port, Shandong, China |

Packing details | Fumigation-free wooden case outside, stretch film inner |

Relevant spare parts | free, delivery with processing line |

Guarantee | Within 12 months |

Oversea service | Provide installation and commissioning after machine arrived your factory |

Payment terms | 30% is paid by T/T as the down payment, 70% is paid by T/T orL/C before shipment. |

Delivery time | 30days after receipt the deposit |

Pre-shipment | When it finished, we will invite you to our company to inspect machines, when no problem, we will arrange the shipment |

12.Saibainuo company:

Saibainuo is aleading manufacturer of high quality twin screw and single screw extruders for food industries.We have almost 12 years'experience of working with our customers providing specialist designs and practical

Factory standing area:30000 square meters

Workshop standing area:20000 square meters.

Office area:4 floor with 600 square meters.