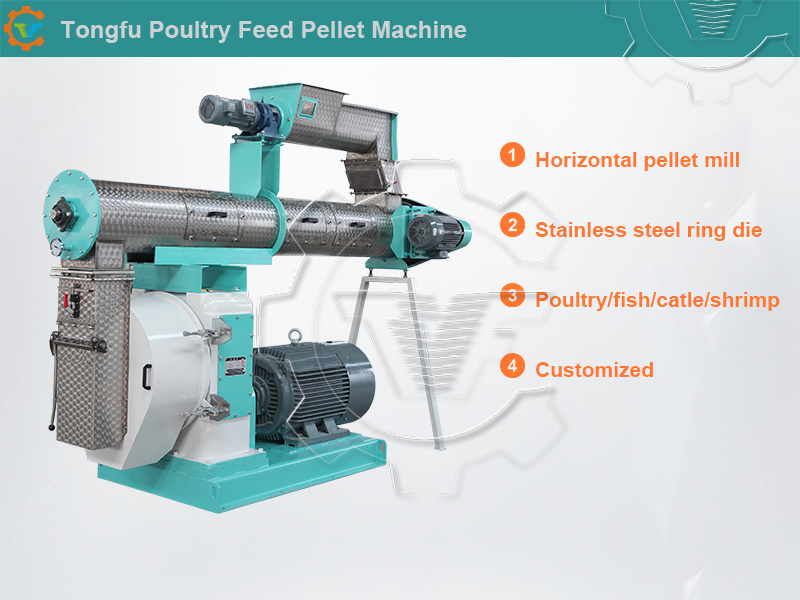

Tongfu Pelletiser Features and Charactors

1. This series pelletiser suitable for making all kinds of animal feedstuff. Which capacity 1000-400000 kg for feed factory .

2. The pelletiser can be match different size of ring die hole size , such as φ1.0,φ1.2,φ1.5,φ2.0,φ2.5,φ3.0,φ3.5,φ4.0,φ4.5,φ5.0,φ6.0,φ8.0 , always for making shrimp, fish feed to use for φ1.0--3.5 ring die ; chicken feed for φ3.0; Swine feed for φ3.0--4.5; Cattle, horse for φ6.0--8.0).

3. The pelletiser adopt imported SKF or NSK bearings, the motor brand is Siemens or china famous Wannan brand .

4. Driven by gear .more strong than by belt, and the capacity 10% higher than by belt .

5. The pelletiser also matched the safty equipment , once overload , the safty pin will crack, to protecting the machine lifetime .

Tongfu Pelletiser Structure and Function

1.Adopted pheroidal graphite cast iron structure and permanent magnet device, aerodynamic technology reduces the temperature in pelletizing chamber to around 90°C for machine works continuously.

2.Treated by hardness quenching and milling machine,the gears maintain high concentricity with the shaft, Thus ensuring a good performance and large capacity than belt driven models.

3.With lubrication system, you can add grease to main shaft without powering off the machine.

4.Equipped with an advanced compensation serpentine-spring coupling which connects the pelletizing chamber with the motor to increase safety and stability.

5.Conditioners can be mounted above pellet machine where liquids such as water and molasses can be added to improve palatability. The more conditioner, the higher feed pellets quality.

Tongfu Pelletiser Technicals

| Model | Power(kw) | Capacity(t/h) | Conditioner(kw) | Pellet Size(mm) |

| SZLH-320 | 37/45 | 2-5 | 3 | 2/3/4/5/6/8/10 |

| SZLH-350 | 55 | 3-8 | 4 | 2/3/4/5/6/8/10 |

| SZLH-420 | 90/110 | 3-15 | 5.5 | 2/3/4/5/6/8/10 |

| SZLH-508 | 132/160 | 5-20 | 7.5 | 2/3/4/5/6/8/10 |

Pelletiser Machine Application in Animal Feed Pellet Production Line

Pelletiser Machine is the most important sections of the animal feed pellet production line, our company supply machines and turn-key projects for you.

1. Raw materials receiving and cleaning section

Cleaning the dust and small debris such as metal or stones. Including convoyers, cleaners, magnetic tubes, dust collector, etc.

2. Crushing section

Crushing the raw materials into powder. Including small silos, hammer mill, conveyors, dust collector, air fan, etc.

3. Mixing section

Mixing different kinds of materials and nutritions. Including mixer, conveyor, etc.

4. Pelletizing section

The most important section of the line, pressing the materials into small pellets. Including conveyors, small silo, pelletiser machine, belt conveyor, sidewall conveyor, etc.

5. Cooling section

Cooling the high temperature pellets to room temperature. Including counterflow cooler, crumbler, conveyors, cyclone, rotary screens, etc.

6. Packing section

Packing pellets into bags 50kg/bag or 1t/bag, etc. ncluding packing scale and sewing conveyor.

7. Electric control systerm & Accessory equipment

Controlling all the machines in the line, including carbinets and cables, etc.

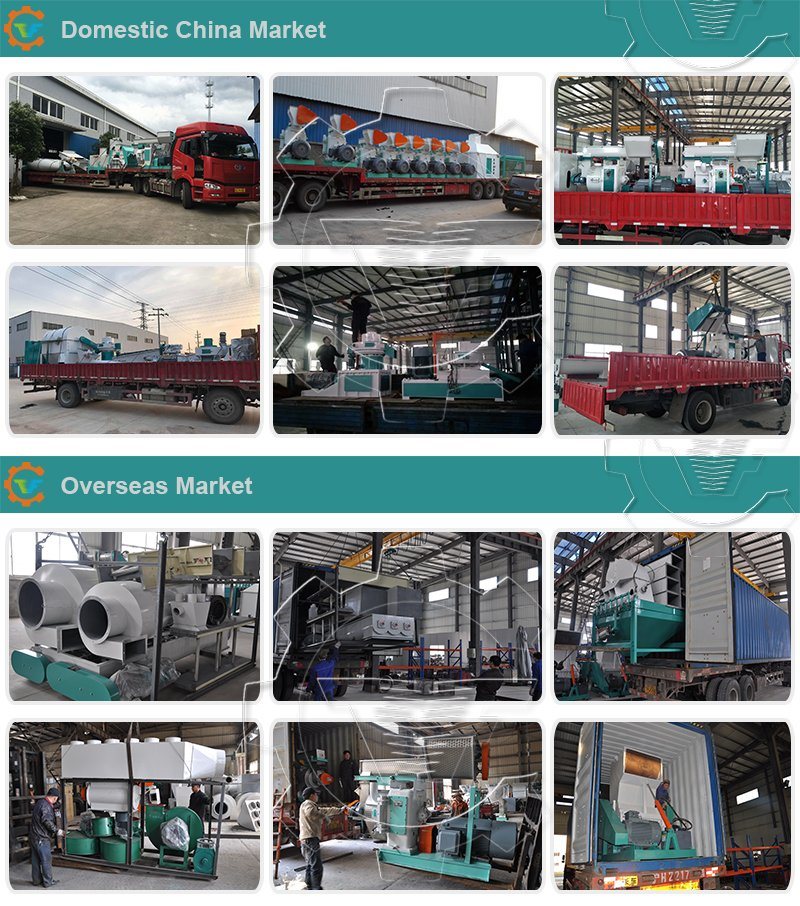

Tongfu pelletiser machine with a group of dynamic engineers full of passion and vitality,advanced technology and production equipment,has been committed to feed machinery,grass machinery,biological fertilizer equipment and automation control equipment,design,manufacture and promotion.

With rich and practical experience,constant innovation and full responsibility to customers,we are doing perfect on every project and every itme with our thoughtful consideration.During the mutual development with customers,we are enjoying great sucess with customers to make customers satisfied.We provide clients with high quality products and fast services.we welcome new and regular customers from all over the world to visit our factory at any time.

We plays a leading role in researching and developing pelletiser machine. Our complete pelletizing production line is characterized by high automatic degree, reliable performance,simple operation and wide application. During past years, hundreds of trading companies choosing to work with us to expand their abroad market and made great success.

Now, our high quality pelletiser machine have been exported to over 30 countries, and numerous plants are installed in Singapore, Malaysia, Vietnam, South Korea, Indonesia, Thailand, Russia, Turkey, Ukraine, Portugal, Hungary, Sweden, Bulgaria, Latvia, Canada, Spain, New Zealand, etc.