Technical description

1、 Introduction

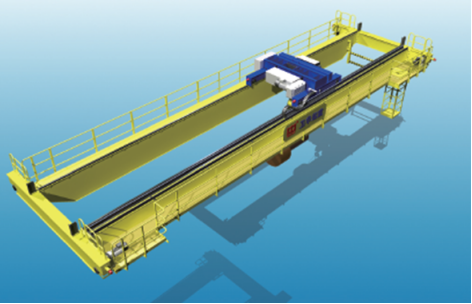

The new European crane (hereinafter referred to as crane) is designed and manufactured according to the relevant European crane standards and Chinese crane standards.

The crane is mainly composed of bridge, trolley, crane operation, electrical part and control room (there is no control room for ground operation). Its lifting capacity includes 5T, 8t, 10t, 12.5t, 16t, 20t, 25t, 32t, 40t, 50t, 63T and 80t. Users can place special orders when they need other lifting weights. The span is 7.5m ~ 31.5m, and its working temperature is -25 ~ +40 ℃. Belonging to the intermediate working system, the crane is widely used. It is not only extremely safe, ergonomically designed, convenient and efficient material transportation, but also its compact size structure is very conducive to saving space. It is mostly used in places such as machinery manufacturing, assembly, warehouse, etc., and is suitable for places such as machinery manufacturing, maintenance, warehouse, etc., but it is not suitable for working in media full of corrosive gases and places with relative humidity greater than 85% where self explosion and fire are dangerous, and it is not suitable for lifting molten metals.

1. metal structure

The main beam is a deflected box beam or section steel beam, and the end beam is welded with section steel or steel plate. The end beam and the main beam are connected together by high-strength bolts.

2. The trolley is equipped with noco imported lifting mechanism.

3. Crane operating mechanism

The crane operating mechanism adopts the form of separate drive, which is divided into two schemes:

a. The motor has the characteristics of soft start. Without connecting the starting resistance and taking other technical measures, the effect of "soft start" can be obtained by directly transmitting power. The motor itself is equipped with a plane friction brake, and the braking speed is adjustable. The impact phenomenon during the start and stop of the crane has been significantly improved. The reduction system adopts closed hard tooth surface gears, which are finely machined with smooth transmission, low noise, large bearing capacity, low temperature rise and long service life.

b. Using sew or Flander's "three in one" operation drive, the performance is superior and the effect is better. (this scheme is adopted for this project)

2、 General outline drawing (see general scheme drawing)

3、 Main performance parameters: attached

4、 Design criteria

1. European standard:

structure and machinery

European Society for material handling part I, design rules for lifting mechanism of heavy lifting equipment

Third edition, October 1st, 1987, Reference No. f.e.m.1.001

The above standards are similar to the latest DIN, ISO, BS and CMAA standards. However, it may be slightly different from the FEM standard.

steel structure manufacturing

Welding standard: din18800, blatt7

Crane design and structure standard: DIN15018, blatt2

Welding grade: din8563, blatt3

brakes and couplings: According to din15434, vde0580, KONE or din15431 standards.

a hook

DIN15401 Single hook

DIN15402 Double hook

DIN15404 Inspection certificate of hook

electrical equipment: Vde0113, VDE0100 and CEE

motor

Iecrecommendations34-1, 34-5 and 72-1.

Select the motor according to the FEM standard and fully comply with the crane standard ikh6.30.01

reduction gearbox: Designed according to iso/dis6336/ii-6336/v (din51150).

Description:

When determining the final design parameters, Demag crane pays attention to the requirements and safety criteria of local customers, so its products can meet the relevant standards of FEM and China when running.

2. Chinese standards:

● gb/t3811-2008 code for design of cranes

● gb/t6067 safety code for lifting appliances

● gb/t5905 crane test specifications and procedures

● gb/t10051 lifting hooks

● jb/t4315 crane electric control equipment

● gb1497-85 basic standard for low voltage apparatus

● jb/dq4658-91 complete set of resistors for cranes

● gb50054-95 code for design of low voltage distribution devices and circuits

● gb50052-95 code for design of power supply and distribution system

● GB50055-93 code for design of power distribution of general electric equipment

● gb/t4942.2-85 degrees of protection of low voltage electrical apparatus enclosures

● gb/t3077-1999 alloy structural steel

● gb/t1591-1994 low alloy high strength structural steel

● jb/t5000.10-1998 general technical conditions for heavy machinery assembly

● jb/t5000.12-1998 general technical conditions for heavy machinery painting

● GSB05-1426-2001 Standard sample card of paint film color

● jb/t7688.1-1995 General requirements for technical conditions of metallurgical cranes

● gb/t13384-1992 general technical conditions for packaging of mechanical and electrical products

● gb/t8918-2006 steel wire ropes for important purposes

● gb10854 outline dimensions of steel structure welds

● gb/t6402-1991 ultrasonic testing method for steel forgings

● gb/14405-1993 general bridge crane

5、 Steel structure

the main beam is a biased box girder or H-beam structure, which is welded by steel plates;

steel plate material is Q235-B;

vertical deflection is l/800;

all steel plates shall be shot blasted to meet the Sa2.5 standard;

carefully inspect and clean the steel before welding, usually by automatic welding machine (MIG or semi-automatic welding);

all welds shall be subject to radiographic non-destructive testing;

the end beam is a rectangular steel pipe or welded into shape, which is positioned and processed in one time on the CNC machine tool, and the steel material is q345-b;

each end beam is equipped with wheels with double rims, buffers and anti derailment protection devices;

a maintenance platform (maintenance walkway) is arranged on the driving side of the crane along the main beam direction of the double beam crane;

the main beam and end beam are connected by high-strength bolts to ensure the accuracy and stable operation of the whole machine.

6、 Institutional part

1 single beam lifting mechanism:

structural form (as shown below)

Motor + brake + reducer + limit switch four in one integrated design, compact structure

lifting motor

Squirrel cage, double winding 6:1 pole changing two speed motor

Protection grade IP55, class F insulation

Power continuity 60% ed

Built in thermistor overheat protection, optimized air-cooled

The motor shell is formed by stamping aluminum tube

reduction gearbox

Fully sealed compact gearbox

The gear material is chromium molybdenum nickel alloy and anti-wear bearing

CNC automatic gear machining center production, hard tooth surface (HRC60), after grinding

Semi grease lubricated, maintenance free

brakes

Electromagnetic disc self-adjusting brake, automatic compensation for brake pad wear, and alarm when the brake pad thickness is insufficient

Service life of brake pads: not less than 1million times of normal use and not less than 500 times of emergency braking

Maintenance free

Normally closed design, when the power is off, the lifting mechanism will

In braking state to ensure safety

Dust proof and asbestos free friction plate

Large friction contact area, adjustable braking torque,

Good heat dissipation performance

limit switches

Cam rotary limit switch

4 fully adjustable upper and lower limit positions

Precise phase sequence control

Slow down before stopping

Decelerate operation to improve brake life and safety

drum

Prolong the service life of steel wire rope, and the weight placement offset is small

The steel wire rope is fixed with a clamp, and at least 2 circles of steel wire rope are fixed

Heavy duty bearing

It is made of seamless steel pipe, and the rope groove is processed

High strength galvanized steel wire rope

rope guide

The wear of steel wire rope is small, the service life is long, and the toughness and elasticity are good

High reliability and convenient disassembly

Even if the hook is lowered to the ground, the tension of the steel wire rope can be maintained

couplings

Gear coupling, material fe52;

hook

The hook group is composed of pulleys and hooks made of large-diameter ductile iron

Adopt anti-wear roller bearing

The hook can rotate 360 degrees

Safety buckle with spring compression can prevent slipping

Hook forgings are quenched and tempered steel 34crmov, Grade T, according to standard din17200

crane and trolley running motors

Squirrel cage variable frequency motor

Stepless speed change operates smoothly without crawling, and reduces the shaking of heavy objects during startup and speed change

Protection grade IP55, class F insulation

Motor power continuity 40% ed

Fully sealed, air-cooled

Built in thermistor overheat protection

The motor shell is formed by stamping aluminum tube

Sew design and manufacturing

traveling reduction gear box of crane and trolley

Three in one structure

The gear material is chromium molybdenum nickel alloy and anti-wear bearing

CNC automatic gear machining center production, hard tooth surface (HRC60), after grinding

Semi grease lubricated, maintenance free

Crane running reducer, manufactured by sew or Flander

crane and trolley brakes

Electromagnetic disc self-adjusting brake

Automatic brake pad clearance compensation

Maintenance free

Dust proof and asbestos free friction plate

trolley and trolley wheels

Surface hardening treatment

Made by Henan heavy industry group

crane and trolley limit switches

Two gear (deceleration + stop) electronic brake limit switch

Decelerate operation to improve brake life and safety

Trigger levers are installed at both ends of the travel direction

With automatic reset function

The limit switch has a solid metal shell with a protection grade of IP65

2. Double beam lifting mechanism:

structural style

The integrated compact design of lifting motor, reducer, drum and lifting limit switch saves users' space. The modular design not only enhances the reliability of the mechanism, but also effectively reduces the maintenance time and cost.

The design of the lifting mechanism strictly complies with the relevant standards of FEM.

Technical features:

aluminum alloy reducer shell

stable operation and low noise

lifetime lubrication (within the safe service life)

double disc electromagnetic disc brake

Lifting motor

The standard lifting motor is a two speed variable-level motor (another variable-frequency lifting motor can be selected by the user), and all motors adopt cylindrical rotors. The standard protection grade of the motor is IP55 and the insulation grade is f. The motor shell is made of aluminum alloy, with good heat dissipation performance. A fan is installed at the end of the lifting motor to enhance the cooling effect. Thermistors (or thermal switches) are embedded in the windings of all lifting motors to prevent possible motor overheating. The thermistor (or thermistor switch) used complies with vde0631 standard.

Before the motor is assembled, the stator winding must be 100% strictly tested,

The test contents and methods are in accordance with the relevant standards of DIN en60204-1 (vde0113),

Specifically include:

interphase resistance

inductance value of pulse voltage

insulation and grounding conditions between windings

resistance of winding

The assembled motor shall also be tested for high voltage resistance according to vde0530 standard: (the test duration is 1 second)

U test voltage = (2 x u rated voltage + 1000V) x 1.2

The frequency conversion lifting motor can be equipped with an encoder according to the use requirements. The encoder is usually directly installed at the fan shaft end of the motor.

Technical characteristics:

small starting current and large torque

soft start, good acceleration performance

long design service life

technical parameters comply with FEM and HMI standards

high speed, low noise

Lifting reducer

The reducer shell is made of aluminum alloy, which is light and corrosion-resistant. The semi greasy lubricant in the fully sealed box enables all gears to be fully lubricated, and there is no need to change the lubricating oil within the designed safe service cycle.

Each gear with surface hardening and high-precision grinding treatment ensures the smooth operation of the reducer.

Technical characteristics:

small size and light weight

stable operation and low noise

corrosion proof, maintenance free

Lifting brake

The lifting motor is equipped with double disc electromagnetic disc brake. The brake is integrated at the end of the motor. When the motor is powered off, the brake will automatically close to prevent the load from sliding. The brake clearance of the brake does not need to be adjusted manually after it is set for the first time (the clearance can be adjusted by the brake spring). When the thickness of the brake pad is lower than the set value, the additional monitoring switch can automatically alarm and prompt the user to replace it. The double disc electromagnetic disc brake is safe and reliable. The braking times can reach 1million, and there is no need to maintain it within the safe service cycle.

According to the safety specifications, the braking torque of the selected brake

Not less than 1.8 times the rated torque of the motor.

Technical characteristics:

fast action and high reliability

maintenance free, self-adjusting

dust proof design, long service life

Drum, wire rope, rope guide

The drum is made of high-quality seamless steel pipes processed by CNC machine tools. After finishing, the rope groove on the drum and the rope guide can effectively prevent the occurrence of loose and disordered ropes.

The steel wire rope adopts high-strength imported steel wire rope with tensile strength of 2160 n/ ㎡, which has good safety and long service life.

The standard rope guide is made of engineering plastic with strong wear resistance and good self-lubricating performance, which greatly reduces the wear of the steel wire rope, the main stress safety component, and thus enhances the safety of the lifting mechanism. At the same time, according to different use conditions, provide heavy-duty guidance rope devices produced by nodular cast iron.

Crane and trolley running mechanism

Years of experience has proved that the trolley running mechanism can adapt to various working environments, such as unstable voltage or even worse working conditions. The running mechanism of the frequency conversion trolley is the standard configuration of the steel wire rope hoist. The frequency conversion speed regulation greatly reduces the shaking of the suspended load in the running process, enhances the safety of the operation, reduces the time required for the operation cycle, and improves the production efficiency.

Two solutions are provided for different working conditions:

Machine structure

The limit size is small, and the effective working area is increased

Reduce plant height and save construction cost

Small size and light weight

three Electrical description

the crane is powered by a safety slide wire;

sliding contact line:

The sliding contact wire is a compact composite sliding contact wire with anti-corrosion and closed insulating shell. Light weight and safety

技术描述

一、概论

新型欧式起重机(以下简称起重机),参照欧洲起重机相关标准,按中国起重机标准设计制造的。

起重机主要由桥架、小车、大车运行、电气部分和操纵室(地面操纵无操纵室)等部分组成。其起重量有5t、8 t、10 t、12.5 t、16 t、20 t、25t、32 t、40t、50 t、63 t、80 t十二种。用户需要其它起重量时可特殊订货。跨度为7.5m~31.5m,其工作温度为-25~+40℃。属于中级工作制,该起重机用途广泛,它不但安全性极佳,设计符合人体工学,物料运输便捷高效,而且其紧凑的尺寸结构非常有利于节省空间。多用于机械制造装配,仓库等场所,适用于机械制造、维修、仓库等场所,但不适用于自爆炸和火灾做危险、充满腐蚀性气体的介质中及相对湿润度大于85%的场所中工作,不适于吊运熔化金属。

1、金属结构部分

主梁为偏轨箱形梁或型钢梁,端梁为型钢或钢板焊接而成。端梁与主梁之间用高强度螺栓组连为一体。

2、小车配用NOCO进口起升机构。

3、大车运行机构

大车运行机构采用分别驱动形式,分为两种方案:

a、电机具有软启动特性,不接启动电阻不必采取其他技术措施,直接送电就可获得“软启动”的效果,电机本身带平面摩擦制动器,制动速度可调。对起重机的启动和停止时出现的冲击现象有非常明显的改善,减速系统采用闭式硬齿面齿轮,磨齿精细加工,传动平稳,噪声低,承载能力大,温升低,寿命长。

b、采用SEW或弗兰德的“三合一”运行驱动,性能优越,效果更佳。(此项目采用本方案)

二、外形总图(见方案总图)

三、主要性能参数:附后

四、 设计标准

1、欧洲标准:

· 结构及机械

欧洲物料搬运学会第一部分,重型起升设备升机构设计规则

1987年10月1日第三版,参考号F.E.M.1.001

以上标准与最新DIN、ISO、BS、CMAA标准相似。但可能与FEM标存在微小差异。

· 钢结构制造

焊接标准:DIN18800,BLATT7

起重机设计和结构标准:DIN15018,BLATT2

焊接等级:DIN8563,BLATT3

· 制动器和联轴器: 按DIN15434,VDE0580,KONE或DIN15431标准。

吊钩

DIN15401 单钩

DIN15402 双钩

DIN15404 吊钩的检验证书

· 电器设备: VDE0113,VDE0100和CEE

· 电动机

IECRecommendations34-1,34-5和72-1。

根据FEM标准选择电机,并完全符合起重机标准IKH6.30.01

· 减速箱: 按ISO/DIS6336/II-6336/V(DIN51150)标准设计。

· 说明:

在确定最终设计参数时,德玛格起重机注重当地客户的要求及安全准则,故其产品在运行时,均能到达FEM及中国的相关标准。

2.中国标准:

● GB/T3811-2008 《起重机设计规范》

● GB/T6067 《起重机械安全规程》

● GB/T5905 《起重机试验规范和程序》

● GB/T10051 《起重吊钩》

● JB/T4315 《起重机电控设备》

● GB1497-85 《低压电器基本标准》

● JB/DQ4658-91 《起重机成套电阻器》

● GB50054-95 《低压配电装置及线路设计规范》

● GB50052-95 《供配电系统设计规范》

● GB50055-93 《通用用电设备配电设计规范》

● GB/T4942.2-85 《低压电器外壳防护等级》

● GB/T3077-1999 《合金结构钢》

● GB/T1591-1994 《低合金高强度结构钢》

● JB/T5000.10-1998 《重型机械通用技术条件 装配》

● JB/T5000.12-1998 《重型机械通用技术条件 涂装》

● GSB05-1426-2001 《漆膜颜色标准样卡》

● JB/T7688.1-1995 《冶金起重机技术条件 通用要求》

● GB/T13384-1992 《机电产品包装 通用技术条件》

● GB/T8918-2006 《重要用途钢丝绳》

● GB10854 《钢结构焊缝外形尺寸》

● GB/T6402-1991 《钢锻件超声波检测方法》

● GB/14405-1993 《通用桥式起重机》

五、钢结构部分

· 主梁为偏轨箱型梁或H型梁结构,由钢板焊接成型;

· 钢板材料为Q235-B;

· 垂直挠度为L/800;

· 所有钢板进行抛丸预处理,达到Sa2.5级标准;

· 焊接前仔细检查和清洁钢材,通常由自动焊机进行焊接(MIG或半自动焊);

· 所有焊缝均进行射线无损探伤;

· 端梁为矩形钢管或焊接成型在数控机床一次定位加工成型,钢材材料Q345-B;

· 每个端梁配有双轮缘的车轮、缓冲器和防出轨保护装置;

· 双梁起重机在沿主梁方向大车驱动侧布置维修平台(维修走道);

· 主梁与端梁采用高强度螺栓连接,确保整机精度和运行平稳。

六、机构部分

1单梁起升机构:

· 结构形式 (如下图)

电机+制动器+减速箱+限位开关四合一集成化设计,结构紧凑

· 起升电机

![]() 鼠笼式、双绕组6:1变极双速电机

鼠笼式、双绕组6:1变极双速电机

![]() 防护等级IP55、F级绝缘

防护等级IP55、F级绝缘

![]() 接电持续率60%ED

接电持续率60%ED

![]() 内置热敏电阻过热保护、优化风冷式

内置热敏电阻过热保护、优化风冷式

![]() 电机壳由铝管冲压成型

电机壳由铝管冲压成型

· 减速箱

![]() 完全密封紧凑型齿轮箱

完全密封紧凑型齿轮箱

![]() 齿轮材料为铬钼镍合金、抗磨轴承

齿轮材料为铬钼镍合金、抗磨轴承

![]() CNC自动齿轮加工中心生产,硬齿面(HRC60)、经过研磨处理

CNC自动齿轮加工中心生产,硬齿面(HRC60)、经过研磨处理

![]() 半油脂润滑、免维护

半油脂润滑、免维护

· 制动器

![]() 电磁盘式自调节制动器,刹车片磨损自动补偿,当刹车片厚度不够时报警

电磁盘式自调节制动器,刹车片磨损自动补偿,当刹车片厚度不够时报警

![]()

刹车片寿命:正常使用不低于100万次,紧急制动不低于500次

刹车片寿命:正常使用不低于100万次,紧急制动不低于500次

![]() 免维护

免维护

![]() 常闭式设计,在断电时起升机构出

常闭式设计,在断电时起升机构出

于制动状态,确保安全

![]() 防尘、无石棉摩擦片

防尘、无石棉摩擦片

![]() 摩擦接触面积大,制动力矩可调,

摩擦接触面积大,制动力矩可调,

散热性能好

· 限位开关

![]() 凸轮旋转式限位开关

凸轮旋转式限位开关

![]() 4个完全可调的上下极限位置

4个完全可调的上下极限位置

![]() 精确相序控制

精确相序控制

![]() 先减速后停止

先减速后停止

![]() 减速操作提高制动器寿命及安全性

减速操作提高制动器寿命及安全性

卷筒

![]() 延长钢丝绳寿命,重物放置偏移小

延长钢丝绳寿命,重物放置偏移小

![]() 钢丝绳用夹具固定,至少有2圈钢丝绳被固定不动

钢丝绳用夹具固定,至少有2圈钢丝绳被固定不动

![]()

重级制轴承

重级制轴承

![]() 由无缝钢管制成,并加工出绳槽

由无缝钢管制成,并加工出绳槽

![]() 高强度镀锌钢丝绳

高强度镀锌钢丝绳

· 导绳器

![]() 对钢丝绳磨损小,寿命长,韧性和弹性好

对钢丝绳磨损小,寿命长,韧性和弹性好

![]() 可靠性高,并方便拆装

可靠性高,并方便拆装

![]() 即使吊钩被降至地面也能保持钢丝绳的张紧

即使吊钩被降至地面也能保持钢丝绳的张紧

· 联轴器

![]() 齿式联轴器,材料Fe52;

齿式联轴器,材料Fe52;

·  吊钩

吊钩

![]() 吊钩组由大直径的球墨铸铁制成的滑轮及吊钩组成

吊钩组由大直径的球墨铸铁制成的滑轮及吊钩组成

![]() 采用抗磨滚子轴承

采用抗磨滚子轴承

![]() 吊钩可以360度旋转

吊钩可以360度旋转

![]() 配备弹簧压紧的安全扣可以防止滑脱

配备弹簧压紧的安全扣可以防止滑脱

![]() 吊钩锻件为调质钢34CrMoV,T级,依据标准DIN17200

吊钩锻件为调质钢34CrMoV,T级,依据标准DIN17200

· 大、小车运行电机

![]() 鼠笼式变频电机

鼠笼式变频电机

![]() 无级变速运行平稳,无爬行,启动、变速时减少重物晃动

无级变速运行平稳,无爬行,启动、变速时减少重物晃动

![]() 防护等级IP55、F级绝缘

防护等级IP55、F级绝缘

![]() 电机接电持续率40%ED

电机接电持续率40%ED

![]() 全密封、风冷式

全密封、风冷式

![]()

内置热敏电阻过热保护

内置热敏电阻过热保护

![]() 电机壳由铝管冲压成型

电机壳由铝管冲压成型

![]() SEW设计、制造

SEW设计、制造

· 大、小车行走减速箱

![]() 三合一结构

三合一结构

![]() 齿轮材料为铬钼镍合金、抗磨轴承

齿轮材料为铬钼镍合金、抗磨轴承

![]() CNC自动齿轮加工中心生产,硬齿面(HRC60)、经过研磨处理

CNC自动齿轮加工中心生产,硬齿面(HRC60)、经过研磨处理

半油脂润滑、免维护

![]() 大车运行减速机、由SEW或弗兰德制造

大车运行减速机、由SEW或弗兰德制造

· 大、小车制动器

![]() 电磁盘式自调节制动器

电磁盘式自调节制动器

![]() 刹车片间隙自动补偿

刹车片间隙自动补偿

![]() 免维护

免维护

![]() 防尘、无石棉摩擦片

防尘、无石棉摩擦片

· 大、小车车轮

![]() 表面硬化处理

表面硬化处理

![]() 河南重工集团制造

河南重工集团制造

· 大、小车限位开关

![]() 两档式(减速+停止)电子制动式限位开关

两档式(减速+停止)电子制动式限位开关

![]() 减速操作提高制动器寿命及安全性

减速操作提高制动器寿命及安全性

![]() 在行走方向的两端各装有触发档杆

在行走方向的两端各装有触发档杆

![]() 具备自动复位功能

具备自动复位功能

![]() 限位开关有坚固的金属外壳,保护等级IP65

限位开关有坚固的金属外壳,保护等级IP65

2.双梁起升机构:

结构形式

起升电机,减速器、卷筒和起升限位开关的一体化紧凑型设计节约了用户的使用空间。模块化设计在增强了机构的可靠性的同时有效降低了维护时间和成本。

起升机构的设计严格执行FEM的相关标准。

起升机构的设计严格执行FEM的相关标准。

技术特点:

l 铝合金减速器壳体

l 运行平稳,噪音低

l 终生润滑(安全使用周期内)

l 双碟电磁盘式制动器

起升电机

标准起升电机为双速变级电机(另有变频起升电机可供用户选择),所有电机均采用圆柱型转子。电机的标准防护等级为IP55,绝缘等级为F级。电机外壳由铝合金拉制而成,散热性能好,起升电机末端安装有风扇以增强冷却效果。所有起升电机的绕组中都嵌入了热敏电阻(或热敏开关)来防止可能发生的电机过热。使用的热敏电阻(或热敏开关)均符合VDE0631标准。

电机组装前,定子绕组都要进行100%的严格测试,

测试内容和方法依照DIN EN60204-1(VDE0113)相关标准,

具体包括:

l 相间阻值

l 脉冲电压电感值

l  绕组间的绝缘及接地状况

绕组间的绝缘及接地状况

l 绕组的电阻

装配好的电机还要根据VDE0530标准进行耐高压测试:(测试持续时间为1秒钟)

U测试电压 = (2 x U额定电压 + 1000V) x 1.2

对于变频起升电机可根据使用要求加装编码器,编码器通常直接安装在电机的风扇轴端。

技术特性:

l  启动电流小,扭矩大

启动电流小,扭矩大

l 软启动,加速性能好

l 设计使用寿命长

l 技术参数符合FEM及HMI标准

l 高转速,低噪音

起升减速器

减速器壳体采用铝合金材料,重量轻,耐腐蚀。全密封的箱体内半油脂状的润滑剂使得所有齿轮能得到充分的润滑,在设计安全使用周期内无需更换润滑油。

每一个经过表面硬化及高精度研磨处理的齿轮确保减速器平稳的运行。

技术特性:

l 体积小,重量轻

l 运行平稳,噪音低

l 防腐蚀,免维护

起升制动器

起升电机配备了双碟电磁盘式制动器。制动器集成在电机的末端,当电机断电时制动器会自动闭合,防止负载滑落。制动器的刹车间隙在首次设定好后无需人工调节(间隙可通过刹车弹簧自行调节),当刹车片厚度低于设定值时通过附加的监控开关可以自动报警,提示用户进行更换。双碟电磁盘式制动器安全可靠,制动次数可达100万,在安全使用周期内无需维护。

起升电机配备了双碟电磁盘式制动器。制动器集成在电机的末端,当电机断电时制动器会自动闭合,防止负载滑落。制动器的刹车间隙在首次设定好后无需人工调节(间隙可通过刹车弹簧自行调节),当刹车片厚度低于设定值时通过附加的监控开关可以自动报警,提示用户进行更换。双碟电磁盘式制动器安全可靠,制动次数可达100万,在安全使用周期内无需维护。

根据安全规范,选用的制动器的制动力矩

根据安全规范,选用的制动器的制动力矩

不小于电机额定扭矩的1.8倍。

技术特性:

l 动作快,可靠性高

l 免维护,自调节

l 防尘设计,使用寿命长

卷筒,钢丝绳,导绳器

卷筒由高品质无缝钢管通过数控机床加工而成,精加工后卷筒上的绳槽配合导绳器可有效防止松绳和乱绳现象的发生。

钢丝绳采用抗拉强度为2160 N/㎡的高强度进口钢丝绳,安全性好,使用寿命长。

标准的导绳器采用耐磨性强和自润滑性能好的工程塑料加工而成,这大大降低了钢丝绳这一主要受力安全部件的磨损,从而增强了起升机构的安全性。同时,针对不同的使用状况,提供由球墨铸铁生产制造的重级制导绳器。

大、小车运行机构

多年的经验证明小车运行机构能适应各种不同的工作环境,比如电压不稳定甚至更糟糕的工况。变频小车运行机构是钢丝绳葫芦的标准配置,变频调速大大降低了吊重物在运行过程中的摇晃,增强了操作的安全性,同时减少了操作周期所需要的时间,提高了生产效率。

针对不同的工况,提供了两种解决方案:

针对不同的工况,提供了两种解决方案:

整机结构

![]() 极限尺寸小,增加有效工作面积

极限尺寸小,增加有效工作面积

![]() 降低厂房高度、节省建筑成本

降低厂房高度、节省建筑成本

![]() 体积小、自重轻

体积小、自重轻

3 电气描述

3 电气描述

· 起重机通过安全滑触线供电;

· 滑触线:

滑触线为防腐蚀、绝缘外壳封闭的紧凑型复合滑触线。自重轻、安装便利、无须维护

使用温度范围:-30°C到+50°C

高纯度电解铝H型导线具有导电率高、电压降低等优点,负载持续率高达80%,压降小

集电器滑行速度高,最快达到250m/min,确保持续供电

· 整机电力供应由手动主电源开关控制,这样在起重机维修期间或长时间不工作时可方便地切断电源;

· 电路回路经过主开关后,再从主断路器到有启动按钮和急停按钮控制的主接触器,之后是各保护开关;

· 起重机具有安全规范要求的保护功能:

失压保护 接地保护 短路保护

过热保护 过载保护 超速保护

限位保护 过流保护 错断相保护等

· 控制电路由变压器输出,控制电压48V,此控制电压器保证当起升和大车、小车运行同时发生时,具有足够的功率输出;

· 起重机由手电门或遥控器控制,所有起升和行走的动作都是独立的且可同时操作。

· 地操手电门防护等级IP65,用软细钢丝悬挂,手电门配置独立滑道,与小车机构的拖缆滑道分离,可沿主梁自由移动,按钮寿命不低于50万次。

· 进口按键式遥控器或摇杆式遥控器其发射手柄具有重量轻,携带方便、防碰撞、按键轻巧等优点内部抗干扰能力强。能在出现异常时及时关断输出。该遥控器配合有效地控制回路可实现驱动电机的启动、停止、调速、故障复位和制动。

· 操作方法与地面操作手柄的操作方法非常相似。首先打开钥匙开关,旋起急停按钮,按下启动/警铃按钮启动起重机的系统电源,同时警铃声响。再按铭牌标示的方向按下相应机构的方向键或摇动相应机构的操作杆即可。

· 遥控器在250米内任意位置操作时确保无信号盲区。

· 控制箱体由钢板制成,表面经防腐处理。打开箱盖需要特制的钥匙或起子。内部零件布局合理,便于维修;

· 控制箱保护等级IP55,有防水保护功能;

· 环境温度:<45°C,湿度<90%;

· 起重机的主电源为三相四线380V(+/-10%),50Hz(+/-5%);

· 起重机用的固定电缆是多线芯型,塑料绝缘。控制电缆采用截面面积至少1.5mm2的多股铜芯电缆。其它电缆的尺寸均符合国际安全规范;

· 所有电线都有颜色、数字或线号标记,易于识别。所有外接线缆都带线号标记。固定电缆布置在走线槽内或有保护套管(镀锌钢管);

· 小小车拖缆系统:

小车拖缆系统包括:弹性扁电缆、拖缆小车(带托架)、滑槽

扁电缆采用具有良好弹性的橡胶绝缘

电缆固定并悬挂在拖缆小车的小车托架上

拖缆小车在滑槽中移动,工字梁滑槽通过支撑杆与主梁连接

小车托架使在任何情况下各拖缆电缆不会相互干涉

· 所有接触器等电气元件均采用施耐德产品。

八、表面处理

· 钢板在焊接前都要经过抛丸预处理,等级SA2.5

· 钢结构油漆为A80,涂层总厚度不小于80um

· 主梁钢结构颜色:标准为RAL1028(橘黄色),也可根据用户要求调整。

· 零部件油漆为E120(齿轮箱、电机、吊钩、制动器、小车等)。标准面漆颜色为:

![]() 起升单元 RAL1028(橘黄色)

起升单元 RAL1028(橘黄色)![]()

![]() 电机,齿轮箱 RAL7021(灰黑色)

电机,齿轮箱 RAL7021(灰黑色)

注:可根据用户要求调整

· 外购件保留其原始的油漆标准

· 电气柜内侧也油漆

发运途中,所有金属表面都有防湿防潮保护