Technical description of electric hoist

1. Product overview

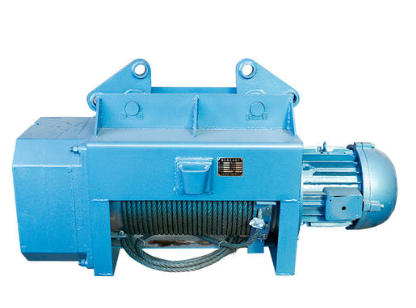

CD1 and MD1 series wire rope electric hoists are improved products on the basis of the original CD and MD models. It has the characteristics of compact structure, light weight, safety and reliability, high versatility of parts, strong interchangeability, high single lifting capacity and convenient maintenance. It is a widely used and popular light lifting equipment at present.

The hoist can be divided into fixed type and trolley type. Fixed type can be divided into "A1, A2, A3 and A4", as shown in Figure 3, which can be directly installed on the frame; Trolley type has running function and can be installed on the track for use. CD1 type is single speed lifting, and MD1 type is normal speed and slow speed lifting.

Our factory mainly produces series electric hoists with a load of 0.25~20t and a lifting height of 3m~30m. We can also design and manufacture non series electric hoists according to your needs.

2. Main purpose

The trolley hoist can be installed on various forms of cranes or hung on I-beam, and the heavy objects can be lifted back and forth in a straight line or curve. The fixed hoist can be installed on the fixed support for vertical or different angle hoisting.

This product is widely used in industrial and mining enterprises, railways, docks, warehouses, stockyards and other places. It is a necessary machine to improve working conditions and labor efficiency in current production operations.

3. Applicable scope and working conditions

This product is suitable for working in an environment where the temperature is -25 ℃ ~+40 ℃, the humidity is ≤ 85%, the altitude is below 1000m, and there is no fire, explosion hazard and corrosive medium. It is forbidden to lift molten metal, toxic, flammable and explosive substances. When used in this environment, BCD explosion-proof electric hoist designed and manufactured according to standard jb5897-91 shall be used. The applicable power supply is AC three-phase, 50Hz, 380V; The working type of this product is intermediate. When the working level of the mechanism in use is increased by one level, its rated lifting capacity must be reduced by 20%.

4. Product specification and model

4.1 example of specification and model description

CD1 is constant speed (MD1 is constant speed / slow speed)

4.2 main parameters of technical performance and overall dimensions of CD1 and MD1 series electric hoists (attached table).

5. Transmission structure and working principle

CD1 and MD1 electric hoists are mainly composed of three parts. One is lifting mechanism; The second is the operating mechanism (not for the fixed type); The third is electrical devices.

5.1 lifting mechanism

The hoisting mechanism is driven by the hoisting motor through the coupling through the reducer hollow shaft to rotate the drum, so that the steel wire rope wound on the drum drives the hook device to rise or fall.

When the lifting height is h=6m, a claw coupling is used to connect the motor shaft and the input shaft of the reducer. When h ≥ 9m, an intermediate shaft and a rigid coupling are added. When h ≥ 18m, a support frame is equipped to strengthen the rigidity of the intermediate shaft to ensure smooth rotation.

5.1.1 lifting motor

The lifting motor adopts the conical rotor motor with large starting torque to adapt to the frequent direct starting in the intermittent work of the product. CD1 hoist is equipped with ZD single speed motor; MD1 hoist is equipped with ZDS double speed motor. The ratio of normal speed to slow speed of ZDS motor is 10:1.

5.1.2 reducer

The 0.25 hoist reducer is a spur gear planetary transmission mechanism, and the other reducers adopt helical gear three-stage reduction. Gears and shafts are made of alloy structure or high-quality carbon steel, and their reliability and service life are ensured by appropriate heat treatment. The box and cover are made of cast iron, with good vibration damping and reliable sealing.

5.1.3 reel setting

The drum is made of cast iron or seamless steel pipe, and uses splines to transmit power; The drum shell is welded with steel plate.

The drum device is the central part of the hoist. Its upper part is connected with the operating mechanism through the balance beam, and its two ends are respectively connected with the lifting reducer and motor. Its lower part works together with the hook device through the steel wire rope. The front and upper part of the outer cover is installed with the limiter guide rod device.

5.1.4 hook device

The hook is forged with special steel and connected with the shell through the hook beam with thrust ball bearing, so that the hook can operate freely. The hook device of 5t and below is of single sliding wheel type, and that of 10t and above is of double sliding wheel type.

5.2 operating mechanism

Electric trolley, running TV, running reducer, driven trolley, etc. together form the running mechanism. The main engine is suspended for reciprocating movement. Its running speed is generally 20m/min, or 30m/min. When the lifting height of 1~5t is ≥ 12M, add a driven trolley.

5.3 electrical devices

The electrical device of CD1 and MD1 hoist is composed of electrical control box (0.25t none), button switch, limiter and connecting wire.

The operating voltage of the button switch is generally 380V or 36V. According to the direction symbol shown on the button switch, press the city button correctly, and the action of the hoist can be controlled through the pull in and disconnect of the relay in the control box.