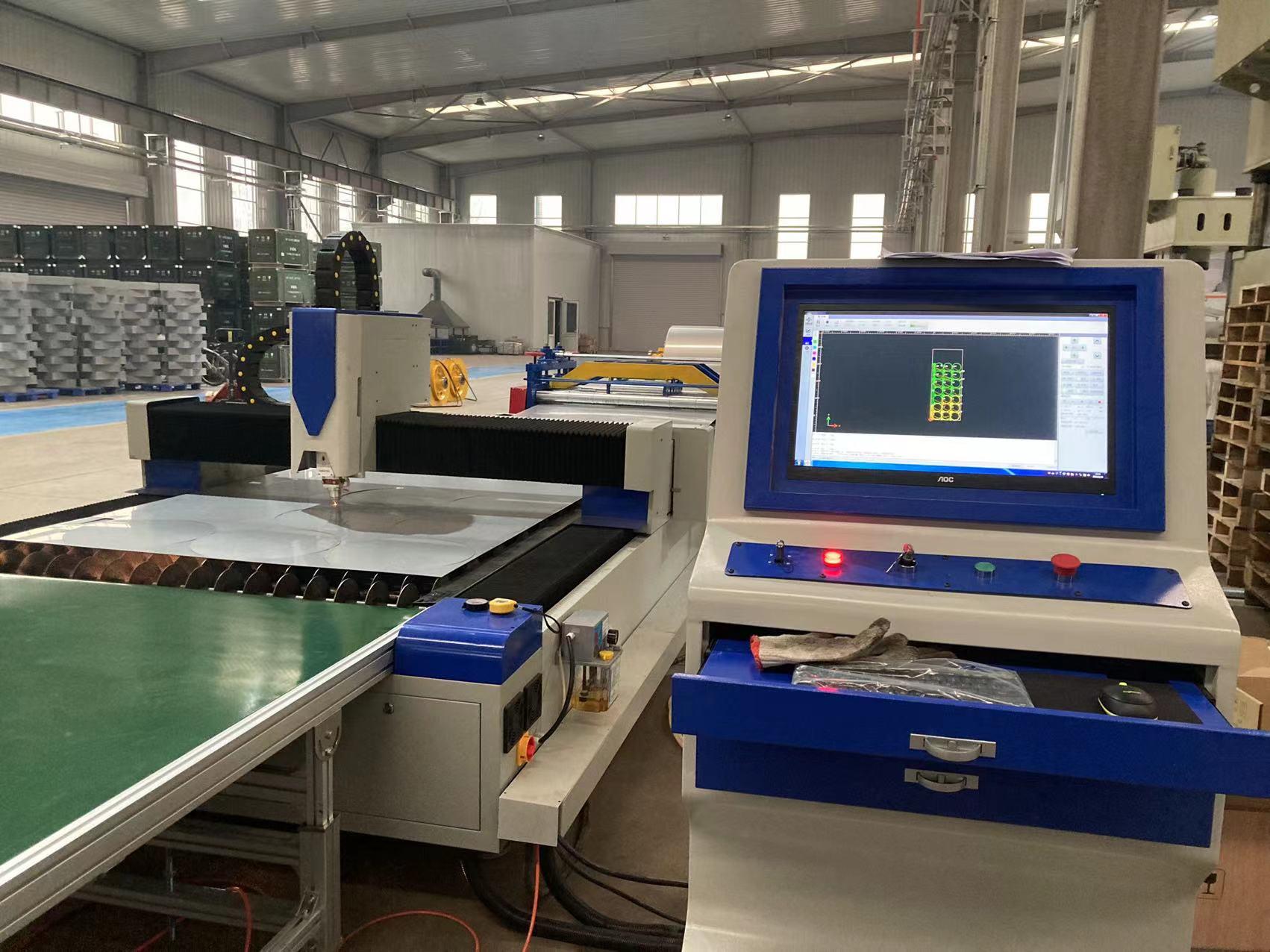

Jinan Guanghe CNC machinery Co., LTD., the company is located in the beautiful Shandong Jinan. Factory covers an area of 10000 square meters, production and sales personnel 60 people, is a collection of scientific research, production, sales and after-sales service for the integration of technology companies, the company is mainly engaged in: CNC optical fiber laser cutting machine, optical fiber laser welding machine, CNC plasma cutting machine, CNC automatic feeder, CNC automatic feeding laser cutting machine production sales

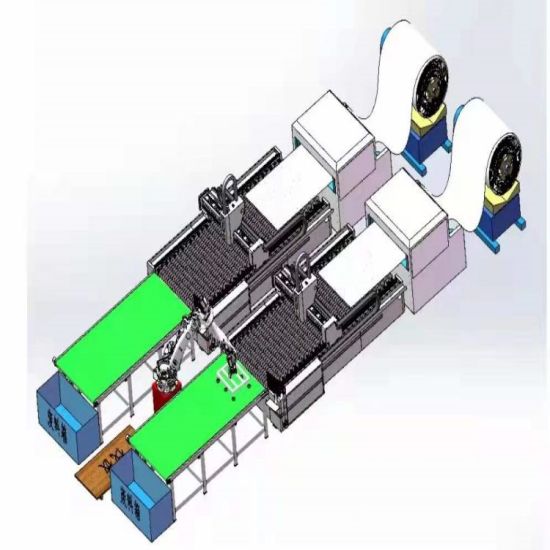

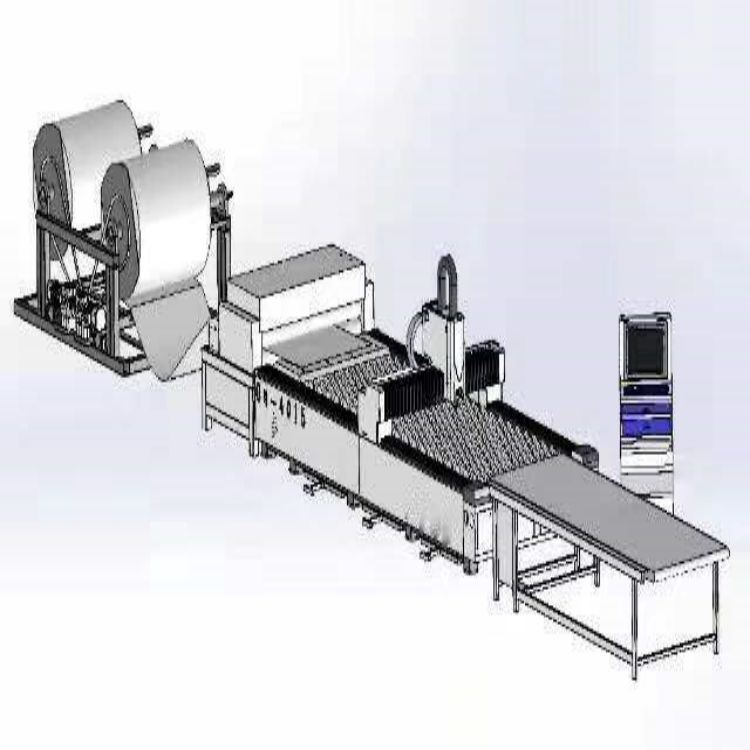

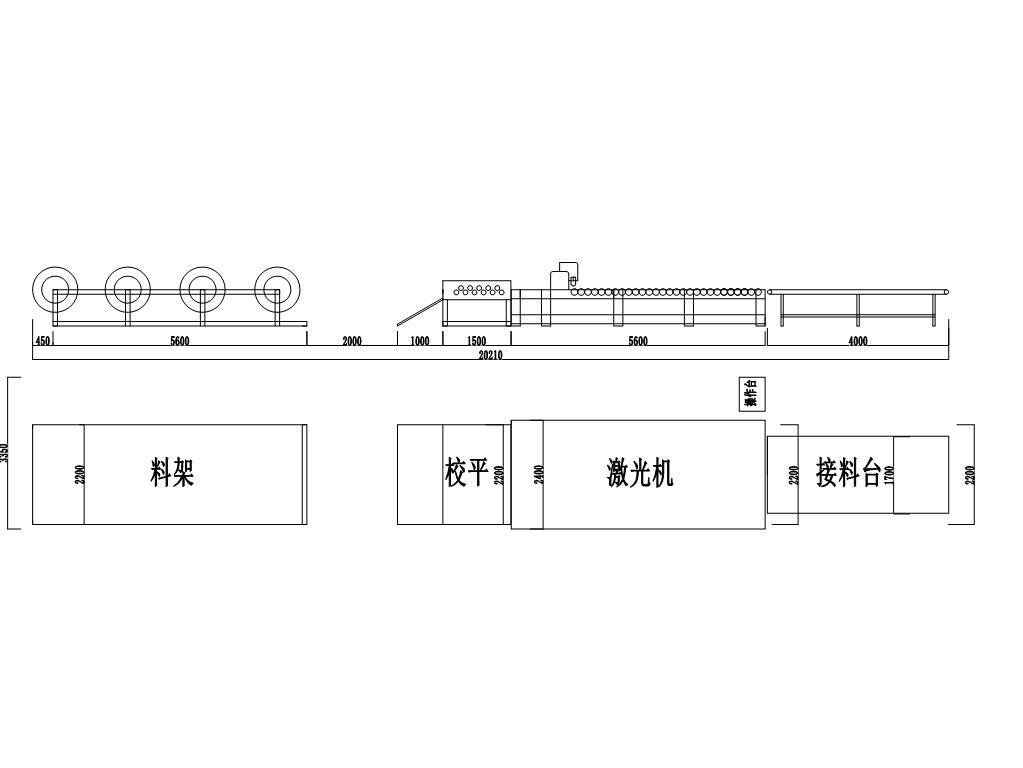

One, automatic feeding fiber laser cutting machine introduction Laser cutting automatic rotation machine:

including rolling material rack, leveling device, laser machine bed body, material receiving platform, automatic rotation components;

Working principle: Leveling machine for the first time into the coil material by leveling after the access to the laser cutting platform for cutting, cutting after the completion of the leveling machine automatic feeding and rotating platform automatically finish the cutting parts to the platform, leveling machine feeding system is running after the completion of cutting the second layout diagram, the serial number of the first materials can be collected at the same time, This reciprocating work greatly improves the overall machining speed and efficiency.

Two, automatic feeding laser cutting machine features

1 cutting efficiency is higher, reduce the plate loading time, only need to pick up waste efficiency increased 2 times

2. Improve the use efficiency of the plate, to achieve the use of the number of cutting, to avoid the need for a fixed length of each plate after the defect of compensation.

3. Reduce manual labor intensity. There is no need to set the size of the material, do not need to lift the plate. Greatly improve work efficiency.

4 can realize a system control, automatic sorting processing, manual integration. The operation is simple and easy to use, and ordinary machines need to import graphics every time more humanized.

5 laser head, laser perfect cooperation, to achieve machine capacity plate speed.

Packing &Shipping

Packing &Shipping1.Standard plywood case, its compressive strength and bearing quality is better.

2.the board area is bit, the soil structure is good, it is better in leakproofness and waterproof.

3.when importing, the plywood case is with fumigation-free, the procedure is simple.

4.Delivery Detail: within 3-5 days after received your payment.

Q1 :How about warranty?

A1:3 years quality guaranty, the machine with main parts(excluding the consumables) shall be changed free of charge(some parts will be maintained) when if any problem during the warranty period.

Q2: I don't know which one is suitable for me ?

A2:Please tell me your

1) Max work size:We can do work size .

2) Materials and marking effect:we will check whether our machine is suitable for you or not and choose a most suitable power and optional parts.

Q3:Payment terms?

A3:TT/West Union/Payple/LC/Cash and so on.

Q4:Do you have CE document and other documents for customs clearance?

A4:Yes,we have Original. At first we will show you and And after shipment we will give you CE/Packing list/Commercial Invoice/Sales contract for customs clearance.

Q5:I don't know how to use after i receive Or i have problem during use,how to do?

A5:1) We have detailed user manual with pictures and CD,you can learn step by step.

2) If have any problem during use,you need our technician to judge

The problem elsewhere will be solved by us. We can provide team viewer

Whatsapp/Email/Phone/Skype with cam till all of your problems finished.We can also provide Door service if you need.