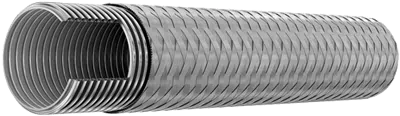

The stainless steel flexible hose 661 consists of parallel stainless steel rings coated with a stainless steel plait. This hose has been designed to transport many types of fluid at a wide range of temperatures.

It is manufactured from a thin-walled smooth tube, welded along its length. The rings are then shaped from hydraulic pressure before the tube is coated in its protective plaited stainless steel sheath.

Hose 661 is used in many industrial applications: Chemistry, petro-chemistry, cryogenic applications, nuclear energy, etc. In particular, thanks to its resistance to high temperatures, regardless if this temperature originates from the transported fluid or the environment of the hose. However, torsion must be avoided and the hose has to be fitted on static installations or installations with cyclical movements of small amplitude.

Hose 662 is a variation of 661; its rings are closer together, thus granting it less flexibility.

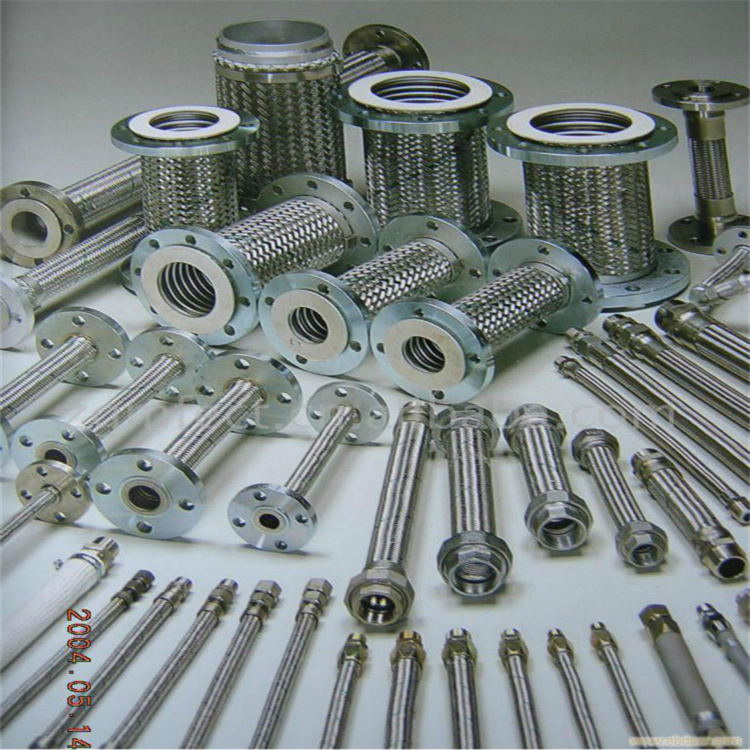

We manufacture our flexible hoses by welding any type of metal connectors to our hoses: BSP or NPT threaded connectors with or without hex nuts, 3-part connectors, rotating female connectors with sealing cone, rotating or fixed flanges, etc.

Caractéristiques techniques:

Tube : AISI 316 L

Reinforcement : 1 stainless steel braid AISI 304

Température : Optimum resistance from –270°C (liquid helium) to 600°C subject to the above considerations.

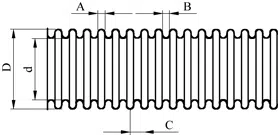

Annularly normal corrugatedAnnularly highly flexible corrugateRatio T°/working pressure}

| Annularly normal corrugated | |||||||||||

| Part N° | Inner diameter | Wall thickness | Dimensions | Bend radius | Working pressure to 20°C | ||||||

| A | B | C | d | D | Tolerance | ||||||

| mm | inch | mm | mm | mm | mm | mm | mm | mm | mm | bar | |

| 9966104 | 6 | 1/4” | 0,18 | 1,16 | 0,85 | 2,00(+ 0,05) | 6,1 | 10,07 | +- 0,1 | 60 | 150 |

| 9966105 | 8 | 5/16” | 0,18 | 1,32 | 0,92 | 2,20(+ 0,05) | 8,4 | 13,6 | +- 0,1 | 124 | 132 |

| 9966106 | 10 | 3/8” | 0,18 | 1,42 | 1,22 | 2,60(+- 0,07) | 10,1 | 15,6 | +- 0,1 | 130 | 100 |

| 9966108 | 12 | 1/2” | 0,15 | 1,86 | 1,32 | 3,10(+ 0,10) | 12,5 | 18,3 | +- 0,2 | 140 | 70 |

| 9966110 | 16 | 5/8” | 0,18 | 2,11 | 1,46 | 3,56(+- 0,10) | 16,3 | 23,8 | +- 0,2 | 160 | 65 |

| 9966112 | 20 | 3/4” | 0,18 | 2 | 1,61 | 3,70(+ 0,10) | 20,3 | 28,6 | +- 0,2 | 170 | 43 |

| 9966116 | 25 | 1” | 0,20 | 2 | 1,62 | 3,70(+- 0,10) | 25,4 | 34,3 | +- 0,2 | 190 | 49 |

| 9966120 | 32 | 1”1/4 | 0,20 | 2 | 1,62 | 3,60(+- 0,10) | 34,3 | 43 | +- 0,2 | 260 | 35 |

| 9966124 | 40 | 1”1/2 | 0,25 | 2,76 | 2,26 | 5,00(+- 0,20) | 40 | 52 | +- 0,3 | 300 | 38 |

| 9966132 | 50 | 2” | 0,25 | 2,76 | 2,26 | 5,00(+ 0,20) | 50,5 | 62,4 | +- 0,3 | 320 | 26 |

| 9966140 | 65 | 2”1/2 | 0,30 | 4,5 | 3,6 | 8,10(+ 0,30) | 65,4 | 83,5 | +- 0,3 | 460 | 25 |

| 9966148 | 80 | 3” | 0,40 | 6,5 | 3,6 | 10,10(+ 0,40) | 80,2 | 100,2 | +- 0,3 | 660 | 16 |

| 9966164 | 100 | 4” | 0,40 | 5,5 | 4,8 | 10,30(+ 0,40) | 100,2 | 122,5 | +- 0,5 | 750 | 10 |