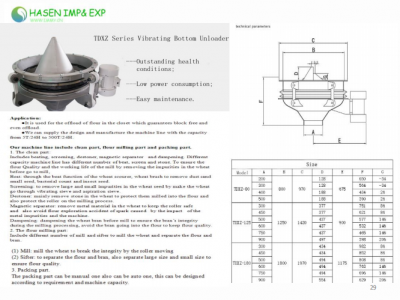

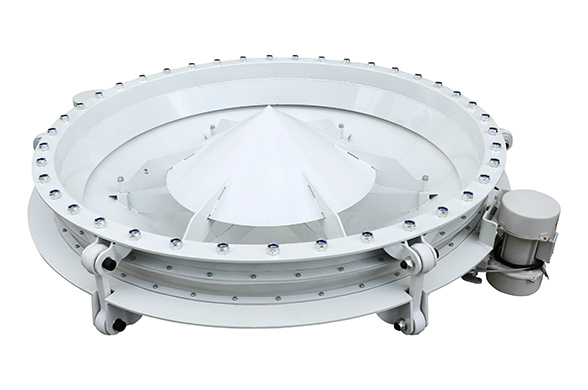

Vibrating Bottom Unloader

Application&advantage

Application:

as concrete silos, steel silos and plastic silos ,and ensure discharging completely for round silo ,square silo and rectangle silo.

Performance Characteristics:

motor to decrease energy consumption.

lubrication is needed in routine maintenance; the structure of vibration discharger is strong and maintenance-free, which reduces the maintenance time to the greatest extent.

are all adopted streamlined geometry design ,ensure the discharging completely without any automatic grading device; this kind of discharger in dust-proof design to minimize material residue and avoid material residue essentially.

Working principle

This machine is installed under the flour bin/silo bottom, for discharging materials

uniformly with the motion of vibrating. Materials flow down to the discharging

hopper and then under the vibration of motor, materials will flow through discharging

plate evenly and gradually without being blocked.

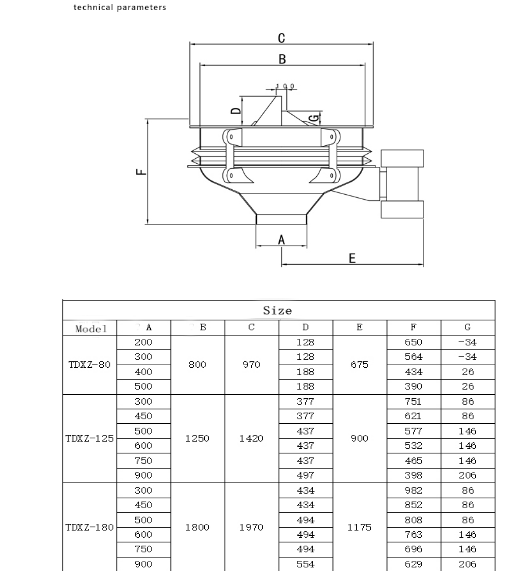

Features

1) Discharging plat taper: 30° for flour and 55° for bran.

2) Vibrate motor can be adjusted to meet various vibration force requirements.

3) Chromed clamps and wear resistant sleeve.

4) Discharge flour equably and continuously.

5) Smooth running with low noise.

Discharging Disk

Conical discharging disk locates at the center part of discharging hopper,

it pushes the material discharging slowly and uniformly from outlet,

meanwhile, it can prevents the material from blocking. |

OFFICE ADD: B/2 Qinglongshan Industrial Zone, Qinglongshan RD,Binhu, Wuxi, Jiangsu,China 214060

Tel&fax: 0086 510 8321 7951 Cell & Whats APP: 008613812016908

E mail: sale@immy.cn;

web: www.immy.cn;

Facebook: TurnkeyGrainMachines or Hasenproducts