Semi Auto Corrugated Cardboard Folding Gluing Machine

Features and characteristics

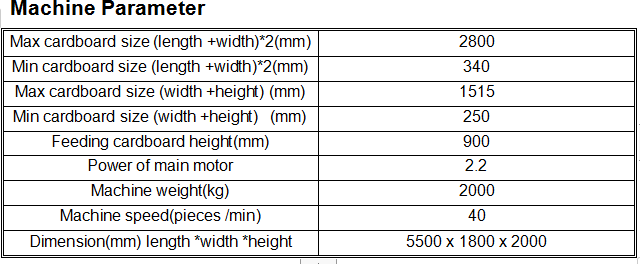

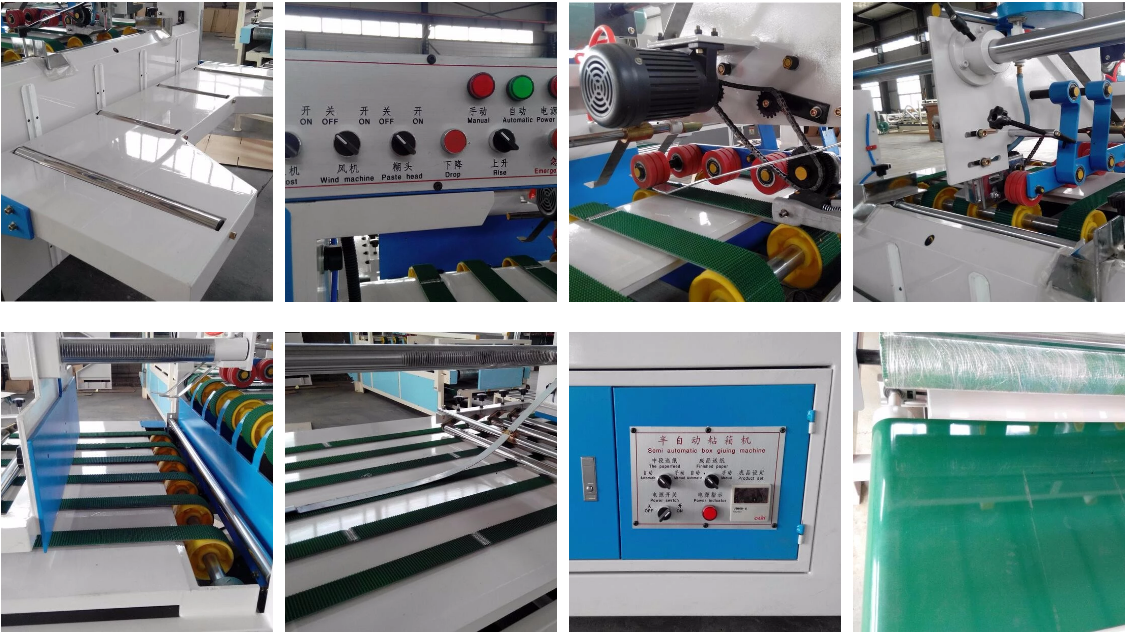

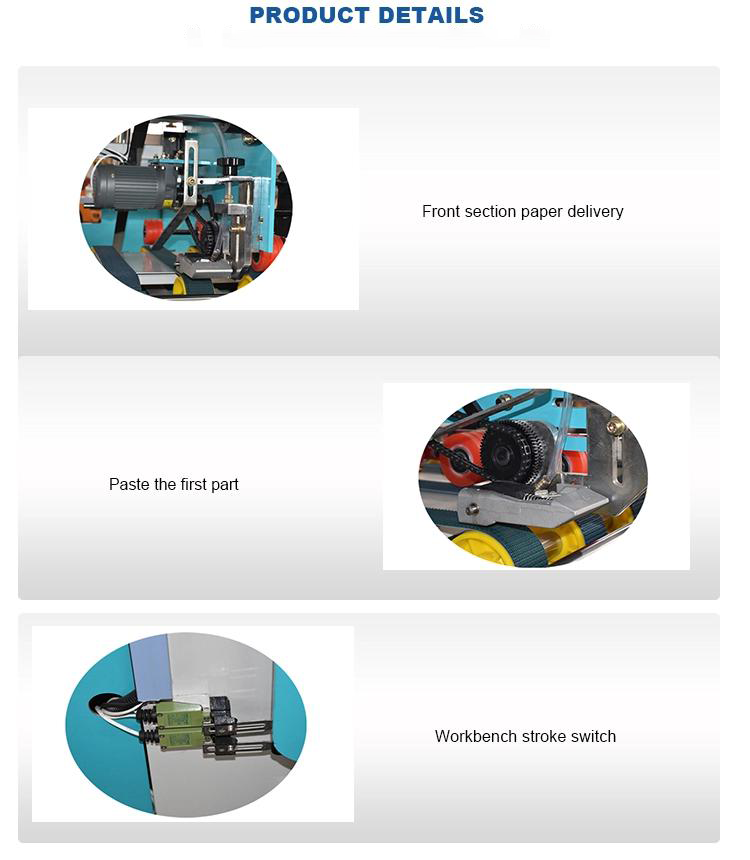

1. Main frame is composed of lifting work platform,front conveyor equipment,front gluing equipment,middle conveyor equipment,middle paper pressing equipment and electrical control equipment.

2.The gluing roller adopts wear-resisting alloy materials, the binder box adopts nylon and wear resistant materials, both of them are vulnerable components, so the operating workers have to use clean water to wash it cleanly.

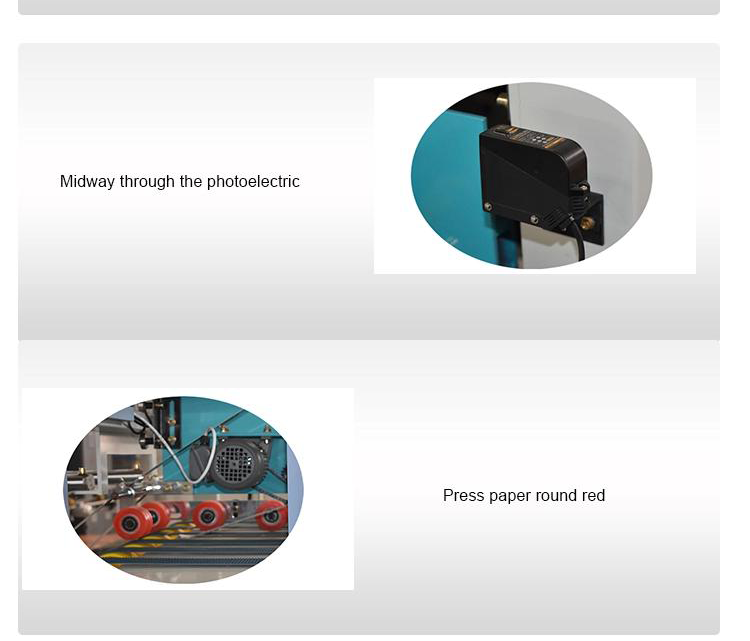

3.Photoelectric control the feeding, reduce labor and improve work efficiency.

4.After gluing and the second pressing , the carton board is smooth and firm.

5.Equipped automatic correction device to make the carton size is correctly, and effectively avoid knife and fork phenomenon.

6.Counting output devices and with the photoelectric correlated mechanism, When reaching to the certain number of carton, it outputs automatically.

7.Press counting output signal, then work automatically, stacking and strapping conveniently.

Working principle

Put the prepared glue into gluing bucket,press each switch button,when everything is in order,turn on the switch below gluing bucket,enable the glue successfully into the head of gluing ,then well remove carton,so one side of the carton can be well-distributed glue when across bottom of the head gluing while the other side of carton can be firmly joint together after middle press- roll pressing.