Corrugated Board 2 Color Flexo Printing Slotting Rotary Die Cutting Machine

Introduction

All wallboard of the equipment are made of HT250 casting materials. After manual treatment, the hardness, density and turnover of the walls are enhanced, resonance is reduced, and noise is reduced, so that the whole machine runs more smoothly and the printing precision is more accurate. The wall is processed by the machining center with high precision and zero error.

The equipment adopts leading edge adsorption paper feeding, the main machine and fan frequency converter control the start and stop, and the high-power dedusting fan cleans the cardboard surface.

The main touch screen and side touch screen adopt the PLC programming system for each part of the industrial control system to realize the human-machine interface humanized control of each part of the operation. The printing accuracy of the machine can be operated on the paper feeding surface, the operating surface and the paper outlet surface. The memory function of the control center is used to separate the wiping plate and memorize the parameters. After the unit is integrated, it will automatically restore the original position, saving time and paper for operation. The front of the host is equipped with a paper output monitoring device, which can observe the paper output at any time during startup and shutdown to ensure the safety of startup and transfer personnel.

All transmission shafts of the whole machine are dynamically and statically balanced. The gears are processed by special technology. All the gears are carburized and ground. The overall hardness is HRC52-58 and the accuracy is Grade 6. The link between the gear and the shaft adopts keyless tension connecting sleeve, which has high concentricity and consistent use time gap of large torque, ensuring the long-term transmission accuracy of the equipment and accurate printing color.

All gears are lubricated by spraying type circulating lubrication, equipped with circulating oil display window to observe the oiling at any time. The bearings of the whole machine are genuine bearings of "Harbin" and "imported NSK".

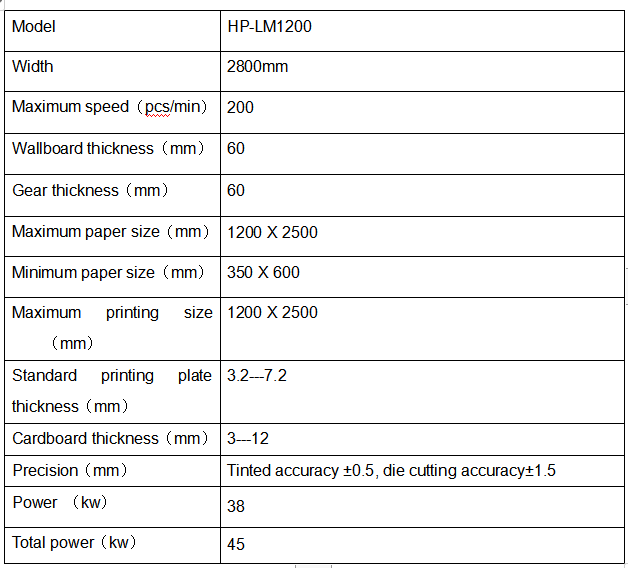

Main Parameter

Main unit

Lead edge feeding unit

1. The paper feeding adopts the most advanced leading edge paper feeding technology, and the material of the paper feeding wheel shaft is bearing steel.

2. The control panel is equipped with a 10-inch human-machine interface color touch screen, which can realize the communication operation of the paper feeding section, printing section, slotting section, and die-cutting section, and can control and display the current phase operation, the speed of the whole machine, and the count and stop to change the order. , plate lift delay, adsorption fan constant speed adjustment, alignment time, continuous, spaced and other system settings, man-machine dialogue or manual electronic control of each part of the dual operating system, the adjustment speed is fast, the operation is safe and easy.

3. The suction fan assists paper feeding, and the air volume can be adjusted in each section according to the size of the cardboard. The motor is a frequency converter controllable motor, which reduces power loss and saves costs. The dust removal fan is a powerful frequency converter controllable motor, equipped with multiple dust removal brushes to remove impurities on the surface of the cardboard and improve the printing quality.

Printing unit

Printing roller

1. Diameter of printing roller ¢408mm( ¢410mm with plate). Made of high-quality steel, the surface is finely ground, hard chrome plated, dynamic balance correction runs smoothly, and is suitable for high-speed printing. The roller is engraved with reference marks in the horizontal and circumferential directions, which is convenient for hanging and matching printing plate. The ratchet-wheeled fixed plate reel with plate hanging groove is suitable for quick plate change. The horizontal distance adjusted of the printing plate roller is 6mm electric adjustment, the effective adjustment range: 12mm, the printing plate can be corrected when running and stopping.

2. The printing roller phase planetary gear controls the circumference 360° to adjust, the forward and reverse 360° computer control motor operation adjustment, can be operated or stopped, the touch screen automatically displays the adjustment amount, and automatically adjusts after inputting the size. The printing plate roller is automatically reset to zero. The system is equipped with a hanging position. Click the hanging position button, and the equipment will automatically run to a convenient position for hanging the plate, which improves efficiency. The pedal switch is installed for the positive and negative rotation of the plate cylinder, which is convenient for plate changing and cleaning.

Die cutting unit

Die roller (punched bottom roller)

1. The outer diameter of the die roller ¢390mm (including the diameter of the knife template ¢410mm). Use high-quality cast steel material, surface grinding, balance correction, and separate holes to increase the stability of operation, and the shaft is electroplated.

2. The fixed bolt hole of the knife template is 10mm, the horizontal distance is 100mm, and the radial circumference is divided into 18 equal parts. It is suitable for the height of the die cutter 25.4mm. The thickness of the wooden template: 16mm (for three-layer cardboard) and 13mm (for five-layer cardboard).

Rubber roller (upper roller)

1. The diameter of the rubber roller is ¢360mm, and the diameter is 405mm with rubber pad. Quick-change rubber pad, wear-resistant and long life. High-quality cast steel material, quenched and tempered, dynamic and static balance, surface fine grinding, increase operation stability.

2. The gap between the die roller and the rubber roller is adjusted electrically, and the air-locked fixed adjustment mechanism is stable and reliable. The rubber roller has a 50mm horizontal travel device and a speed difference compensation system. Each knife is in a different position and wears evenly, which effectively prolongs the service life of the rubber pad.

Quadruple knife without die cutting board (optional )

1.The lower roller is equipped with four cutter knife to manually adjust the height and length and width of the box; the operation is simple and durable, and the cost of the cutter is saved to the greatest extent.