ntent="" style="background-color:#c5e1b3;padding:0 10px;margin:0;line-height:36px;text-align:left;">Product Description

Water immersion retort uses the unique liquid flow switching technology to improve the uniformity of temperature inside the retort vessel. Hot water is prepared in advance in the hot water tank to start the sterilization process at high temperature and achieve the fast temperature rising, after sterilization, hot water is recycled and pumped back to hot water tank to achieve the purpose of energy saving.

Water immersion retort uses the unique liquid flow switching technology to improve the uniformity of temperature inside the retort vessel. Hot water is prepared in advance in the hot water tank to start the sterilization process at high temperature and achieve the fast temperature rising, after sterilization, hot water is recycled and pumped back to hot water tank to achieve the purpose of energy saving.

ntent="" style="background-color:#c5e1b3;padding:0 10px;margin:0;line-height:36px;text-align:left;">Certifications

Retort is designed and produced according to the requirements of GB150-2011 <steel pressure vessel manufacturing standard>. DTS is identified and has passed through ISO9001, ISO14001 system authentication and also passed America ASME as well as SGS, TUV, BV, EAC rated.

ntent="" style="background-color:#c5e1b3;padding:0 10px;margin:0;line-height:36px;text-align:left;">Product Parameters

| Model | Effective diameter | Effective length | Dimension | Qty of food baskets | Design Temperature | Design Pressure | ||

| L | W | H | ||||||

| DTSJ/10-2 | 1000 | 1800 | 3500 | 1800 | 2800 | 2 | 147ºC | 3.5bar |

| DTSJ/10-3 | 1000 | 2400 | 4091 | 1785 | 3064 | 3 | ||

| DTSJ/12-3 | 1200 | 2400 | 3149 | 1852 | 2177 | 3 | ||

| DTSJ/12-4 | 1200 | 3600 | 5462 | 2851 | 3987 | 4 | ||

| DTSJ/12-5 | 1200 | 4500 | 5408 | 2550 | 3393 | 5 | ||

| DTSJ/14-3 | 1400 | 3200 | 5600 | 2500 | 4000 | 3 | ||

| DTSJ/14-4 | 1400 | 4000 | 6951 | 2421 | 4102 | 4 | ||

| DTSJ/14-5 | 1400 | 5000 | 7600 | 2600 | 4200 | 5 | ||

ntent="" style="background-color:#c5e1b3;padding:0 10px;margin:0;line-height:36px;text-align:left;">Our Advantages

1. Uniform water flow distribution

By switching the water flow direction in the retort vessel, uniform water flow is achieved at any position in the vertical and horizontal directions. An ideal system for dispersing water to the center of each product tray to achieve uniform sterilization without dead ends.

2. High temperature short time treatment

High temperature short time sterilization can be performed by heating hot water in a hot water tank in advance and heating from high temperature to sterilize.

3. Suitable for easily deformed containers

Because water has buoyancy, it can form a very good protective effect on the container under high temperature state.

4. Suitable for handling large packaging canned food

It is difficult to heat and sterilize the central part of large canned food in a short time by using a stationary retort, especially for food with high viscosity.ntent="" style="background-color:#c5e1b3;padding:0 10px;margin:0;line-height:36px;text-align:left;">DTS Technologies

1. Spiral-tube heat exchanger made of stainless steel

Inside tube material is stainless steel 316L, no need to replace the rubber gasket, no need maintenance, corrosion resistance, long service life.

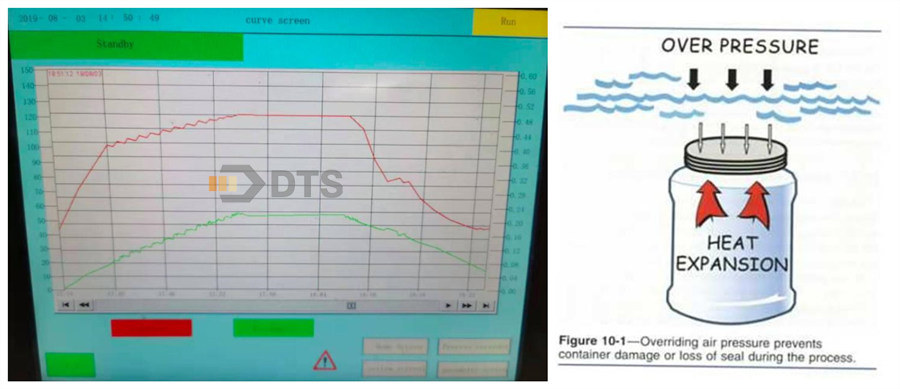

2.Full automatic linear control system

DTS self-studied patented technology D-TOP system can be sensitive to temperature.It can automatically calculate the pressure changes inside the container according to the temperature.And then automatically adjust the pressure inside the retort to get the pressure balance between container internal and external.So it can prevent the package's deformation, keep the package shape.Especially be suitable for aluminum tray products.Pressure was controlled in +/ -0.05 bar with compressed air intake valve and exhaust valve.

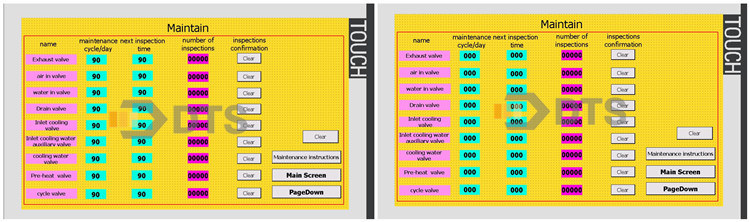

3. maintence cycle and alarm:For main valves, we set the maintenance cycle and time in the PLC, when it arrives, there will be alarm appear to notice.

ntent="" style="background-color:#c5e1b3;padding:0 10px;margin:0;line-height:36px;text-align:left;">Packaging & Shipping

ntent="" style="background-color:#c5e1b3;padding:0 10px;margin:0;line-height:36px;">Company Profile

DTS is the most influential supplier of retort equipment in the food and beverage industry in Asia.Our goal is to become the top international brand in food sterilization industry.We have highly experienced and talent mechanical engineers, design engineers and electrical software development engineers.It is our aim and responsibility to provide the best products and services as well as excellent working environment for our customers.We love what we do, and we fully understand that our value lies in helping customers create value.To this end, we are cautious to develop and design various flexible and customized solutions to meet different customer needs through well communication.