ntent="" style="background-color:#c5e1b3;padding:0 10px;margin:0;line-height:36px;text-align:left;">Product Description

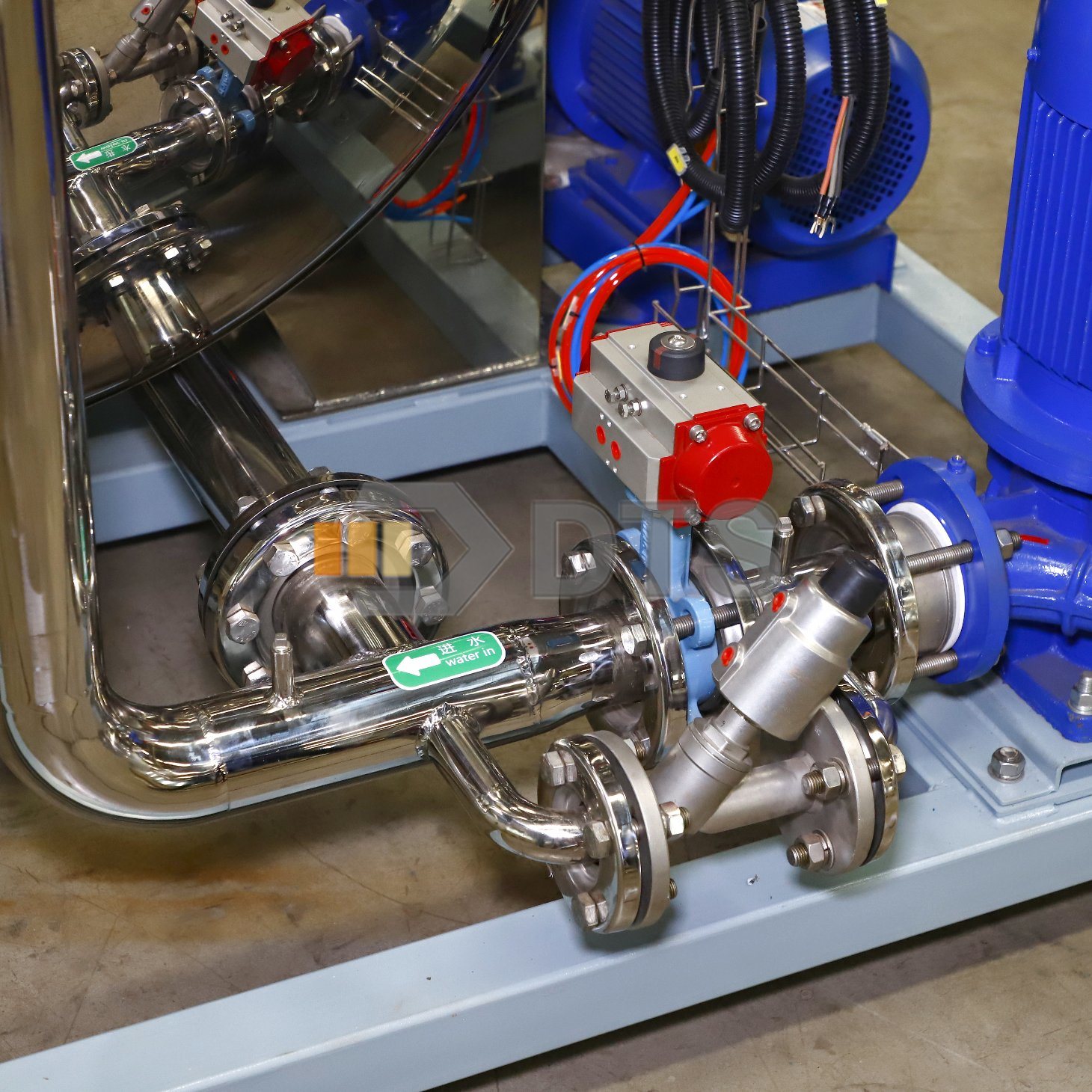

Heat up and cool down by the heat exchanger, so the steam and cooling water will not contaminate the product, and no water treatment chemicals are needed. The process water is evenly cascaded from top to bottom through the large-flow water pump and the water separator plate on the top of the retort to achieve the purpose of sterilization. The precise temperature and pressure control can be suitable for a variety of packaged products. The simple and reliable characteristics make DTS sterilization retort widely used in the Chinese beverage industry.

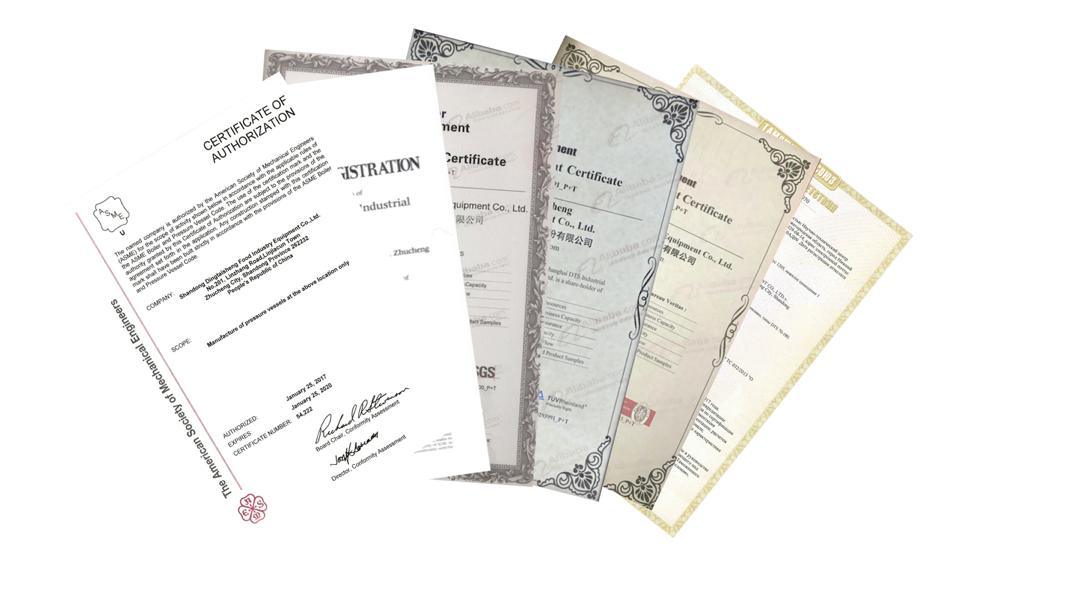

ntent="" style="background-color:#c5e1b3;padding:0 10px;margin:0;line-height:36px;text-align:left;">Certifications

Retort is designed and produced according to the requirements of GB150-2011 <steel pressure vessel manufacturing standard>. DTS is identified and has passed through ISO9001, ISO14001 system authentication and also passed America ASME as well as SGS, TUV, BV, EAC rated.

ntent="" style="background-color:#c5e1b3;padding:0 10px;margin:0;line-height:36px;text-align:left;">Detailed Photos

ntent="" style="background-color:#c5e1b3;padding:0 10px;margin:0;line-height:36px;text-align:left;">Product Parameters

| Model | Effective diameter | Effective length | Dimension | Qty of food baskets | Design Temperature | Design Pressure | ||

| L | W | H | ||||||

| DTSL/10-2 | 1000 | 1800 | 3500 | 1600 | 2200 | 2 | 147ºC | 3.5bar |

| DTSL/10-3 | 1000 | 2400 | 4286 | 1644 | 2407 | 3 | ||

| DTSL/12-3 | 1200 | 2400 | 3149 | 1852 | 2177 | 3 | ||

| DTSL/12-4 | 1200 | 3600 | 4342 | 1897 | 2718 | 4 | ||

| DTSL/12-5 | 1200 | 4500 | 5408 | 2550 | 3393 | 5 | ||

| DTSL/14-3 | 1400 | 3000 | 5500 | 2200 | 4000 | 3 | ||

| DTSL/14-4 | 1400 | 4000 | 6951 | 2421 | 4102 | 4 | ||

| DTSL/14-5 | 1400 | 5000 | 7000 | 2400 | 4100 | 5 | ||

| DTSL/14-6 | 1400 | 6000 | 7900 | 2600 | 4300 | 6 | ||

| DTSL/16-4 | 1600 | 5000 | 6022 | 2624 | 3605 | 4 | ||

| DTSL/16-5 | 1600 | 5600 | 6433 | 2729 | 3712 | 5 | ||

| DTSL/16-6 | 1600 | 7100 | 8080 | 2646 | 3700 | 6 | ||

| DTSL/18-5 | 1800 | 5800 | 7500 | 2800 | 2900 | 5 | ||

| DTSL/18-6 | 1800 | 7500 | 8681 | 2700 | 2600 | 6 | ||

ntent="" style="background-color:#c5e1b3;padding:0 10px;margin:0;line-height:36px;">Our Advantages

1. Accurate temperature control, excellent heat distribution

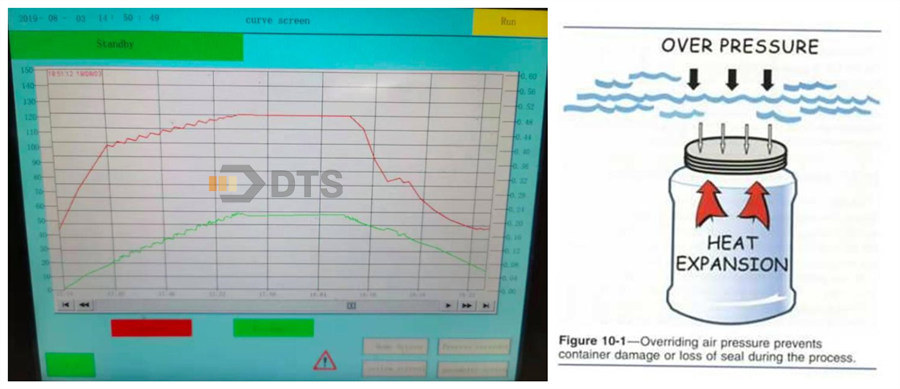

The temperature control module (D-TOP system) developed by DTS has up to 12 stages of temperature control, and the step or linearity can be selected according to different product and process recipe heating modes, so that the repeatability and stability between batches of products are maximized well, the temperature can be controlled within ±0.5ºC.

2. Perfect pressure control, suitable for a variety of packaging forms

The pressure control module (D-TOP system) developed by DTS continuously adjusts the pressure throughout the whole process to adapt the internal pressure changes of the product packaging, so that the degree of deformation of the product packaging is minimized, regardless of the rigid container of tin cans, aluminum cans or plastic bottles, plastic boxes or flexible containers can be easily satisfied, and the pressure can be controlled within ±0.05Bar.

3. Highly clean product packaging

The heat exchanger is used for indirect heating and cooling, so that the steam and cooling water are not in contact with the process water. The impurities in the steam and cooling water will not be brought to the sterilization retort, which avoids the secondary pollution of the product and does not require water treatment chemicals (No need to add chlorine), and the service life of the heat exchanger is also greatly extended.

4. Energy saving and environmental protection

A small amount of process water is quickly circulated to quickly reach the predetermined sterilization temperature. Low noise, create a quiet and comfortable working environment. Unlike pure steam sterilization, there is no need to vent before heating, which greatly saves steam loss and saves about 30% of steam.

ntent="" style="background-color:#c5e1b3;padding:0 10px;margin:0;line-height:36px;text-align:left;">DTS Technologies

1. Spiral-tube heat exchanger made of stainless steel

2.Full automatic linear control system

DTS self-studied patented technology D-TOP system can be sensitive to temperature.It can automatically calculate the pressure changes inside the container according to the temperature.And then automatically adjust the pressure inside the retort to get the pressure balance between container internal and external.So it can prevent the package's deformation, keep the package shape.Especially be suitable for aluminum tray products.Pressure was controlled in +/ -0.05 bar with compressed air intake valve and exhaust valve.

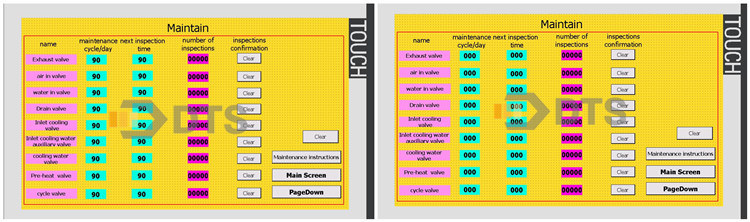

3. maintence cycle and alarm:For main valves, we set the maintenance cycle and time in the PLC, when it arrives, there will be alarm appear to notice.

ntent="" style="background-color:#c5e1b3;padding:0 10px;margin:0;line-height:36px;text-align:left;">Packaging & Shipping

ntent="" style="background-color:#c5e1b3;padding:0 10px;margin:0;line-height:36px;text-align:left;">Company Profile

DTS is the most influential supplier of retort equipment in the food and beverage industry in Asia.Our goal is to become the top international brand in food sterilization industry.We have highly experienced and talent mechanical engineers, design engineers and electrical software development engineers.It is our aim and responsibility to provide the best products and services as well as excellent working environment for our customers.We love what we do, and we fully understand that our value lies in helping customers create value.To this end, we are cautious to develop and design various flexible and customized solutions to meet different customer needs through well communication.