Pneumatic Grain Conveyor

It can be used to conveyor granular materials horizontally, slantly and vertically such as rice, wheat, corn, soybean, sorghum, barley malt, plastic pellets, chips, resins and other granular.This kind of equipment is compact and flexible. It can loading and unloading the material quickly and easily.

Working principle of pneumatic grain conveyor:

Pneumatic grain conveyor is composed of the high pressure blower, air flow control valve, separator tube, air locker, connecting pipe, suction nozzle and conveying pipelines and other components. Its working principle is negative pressure air stream generated by the high pressure blower though the suction nozzle, suctioning the materials into the hose tube, then materials through the separation tube, air and material separated, material fell off into the air locker downward, then materials will be conveyed to the required place by positive pressure air flow. The air separated will go into the blower through the separator tube.

Main features of pneumatic grain conveyor:

1. Strong power and big conveying quantity

2. Flexible application and grain hanging conveyor

3. Advanced technology and cost-saving

4. Safe and simple installation and commissioning.

5. Simple structure and less&easy maintenance.

6. High efficiency and energy-saving.

7. Easy operation.Strong Power Grain Pneumatic Conveyor/Rice Husk Pneumatic Vacuum Grain Conveyor

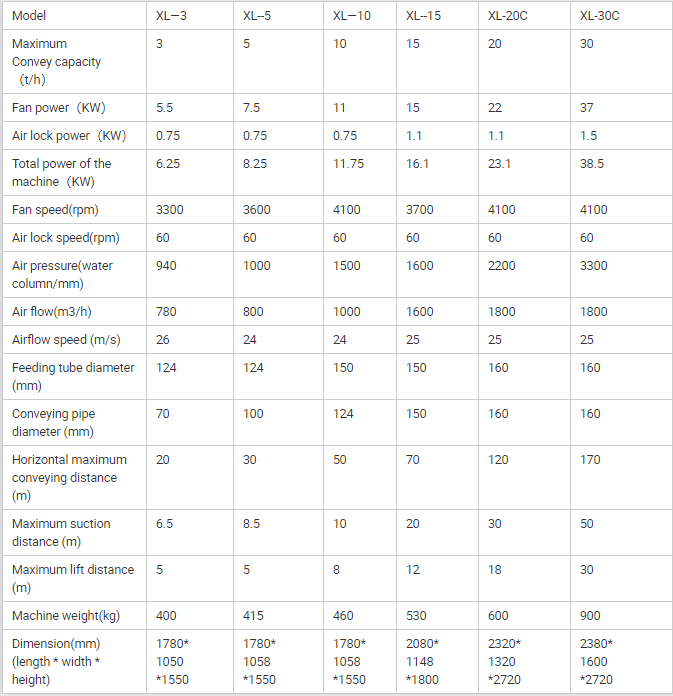

Technical specs of pneumatic grain conveyor:

Wooden Box Package:

After Sales Service

1.Pre-sales Services:

Contact - Design - Discussion (email/call/chatting tools) - Offer - Visiting Invitation & Reception - Establish Primary Trust

2. Selling Services:

Sending the confirmed design and foundation map for building foundation;

Taking photos and videos of the production processes for customers’ reference

Pre-assemble main parts together and test

Paint color and Logo following customers’ requirements;

Arrange customers to come to inspect the finished goods;

lBook the shipping space in advance to ensure delivery on time.

Monitor containers loading and packing, such as wooden boxes packing, steel wires reinforcement.

3. After-sales Services:

Tracking the vessels and the estimated arriving date;

Sending all necessary documents and assist to fetch the goods smoothly;

Dispatch experienced engineers to installation & commission, and training;

Regularly learning the equipment running situation;

Remote control is available at any time;

Warranty: 12 months

Spare Parts: sending through DHL/FEDEX/TNT