ScopeOfApplication:

Ethylene oxide sterilizing cabinets are used for the sterilization of articles that are not resistant to high temperatures, moisture, and difficult to penetrate.

EO has a wide range of clinical applications, and equipment used in EO sterilization includes:

Hard and soft endoscopy,Medical equipment,Instruments,Rubber products,Plastic products.

Full-automatic control system

One-click start-to-end, and the whole process is completed automatically

Display status

The data of each item in the whole process of sterilization can be printed out by using a micro printer, which can be saved permanently.

Vacuum system

The oil-free vacuum pump is simple and convenient, the vacuum rate is fast and the service life is long.

Heating system

Adopt flame retardant explosion-proof electric heating system, six-sided heating, more uniform and accurate temperature, with double temperature control protection

The entire sterilization process is completely under negative pressure to ensure that the gas does not leak. The built-in temperature probe can adjust the temperature in real time. The built-in humidity probe ensures that the relative humidity is >65%. computerized operation.

Helps you control load and turnaround times to meet peak usage demands. Multiple installations allow simultaneous sterilization and automatic venting.

Sterilizer combination materialsand functions:1. Sterilization room with 304 imported stainless steel three temperature control

2. Double protection door

3. Outer box 1.2 mm high quality steel plate paint

4. Sterilization process Automatic computer control

5. Leak detection function

6. All over the machine water temperature control system

7. Increase the sterilization effect of the humidification system

8. The end of the sterilization of ethylene oxide and water vapor analysis system to ensure the safety of operators

9. The use of pure ethylene oxide single filling quantitative filling more secure

10. Single wash pure ethylene oxide and mixed ethylene oxide dual configuration can be used in this machine

11. Automatic microcomputer digital or digital LCD control system12. Sterilization purposes: not temperature, heat, wet items for sterilization.

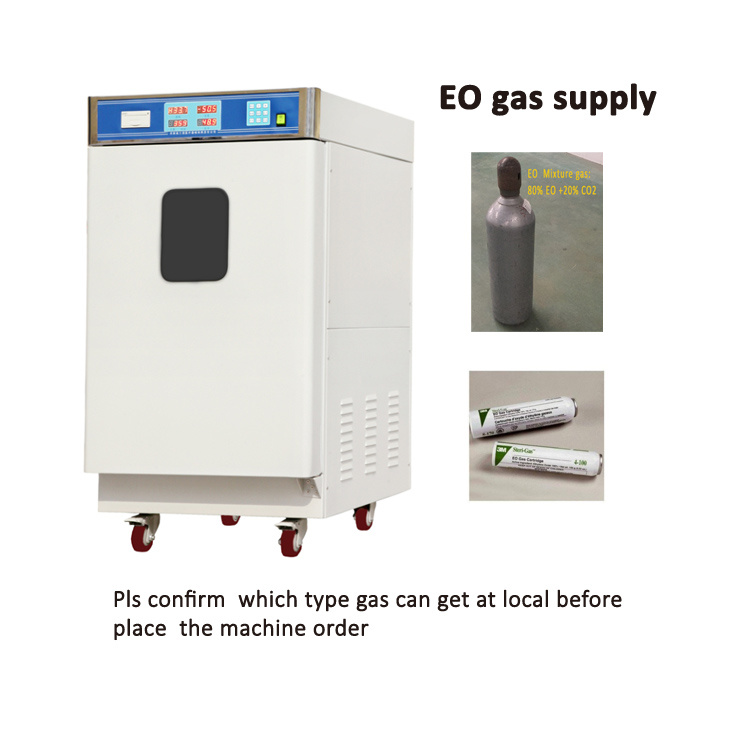

13. Sterilization method: aluminum alloy single cans plus 100% ethylene oxide gas or mixed ethylene oxide gas.

14. Action valve: Pneumatic valve.

15. Neck equipment: stainless steel equipment and high-quality aluminum alloy.

16. Heating method: electric heating film uniform heating.

17. Printing system: sterilization process using a micro-printer will be the whole process of printing and save the sterilization.

18. Appearance: using automatic lift door.

Product Parameters

| Product name | Autoclave Single EO Gas Sterilizing Chamber |

| Product form | Manual door vertical |

| Heating mode | electrical heating |

| Power supply | AC220V,50Hz |

| Temperature display | LEDdigital |

| Sterilizing chamber material | 304 anti-corrosive stainless steel |

| Material of outer box | Carbon steel (1.8mm thick) baking powder |

| Sterilization temperature | 50ºC±3ºC |

| Working pressure | -60kpa |

| Sterilization humidity | 45%-75% |

| Selected gas | mixed gas or pure gas |

| Ethylene oxide sterilization concentration | 1g/L |

| Sterilization time | 0-99 hours adjustable |

| Vacuum speed | 15 minutes to -60kpa |

| Air replacement | Automatic air exchange, 5 periodic breaths at intervals of 15 minutes |

| Full automatic control system | One-click start to end, the whole process is completed automatically |

| Display status | Display temperature, humidity, pressure, sterilization time, residual gas treatment time, number of times |

| Printer | Microprinter is used to print out every minute data during sterilization, which can be stored permanently. |

Company Profile

FAQ

1.Who we are?

We are based in Jiangsu, China, near Shanghai,start from 2008.We arethe earliest manufacturer of export funeral productsin China,sell to South America(20.00%),Southeast Asia(20.00%),North America(10.00%),Africa(10.00%),Eastern Asia(10.00%),Western Europe(10.00%),Southern Europe(10.00%),Domestic Market(10.00%).

We are factory which hasover 20 years' manufacturingexperience,customers are welcome to inspect the factory!

3. How can we guarantee quality?

Always a pre-production sample before mass production;

Always 100% test before delivery.

Always final Inspection before shipment;we are constantly developing and implementing new standards for product quality and service efficiency.

4.Whatcan you buy from us?

Hospital Bed,Medical Equipment,Operating Table,Medical Trolley,Funeral Product,Clinic lab equipment,physical equipment...

5.Whatwarrantydo your products have?

We provide a standard1 year warranty,optional to be increased. The product that is damaged or fails due to the manufacturing problem within one year after the purchasing date will gain free spare parts and assembling drawings from the company.

Beyond the period, we will charge the accessories, but thetechnical service is still free.

our after-sales department will periodically follow up customers!

6. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,Express Delivery...

Accepted Payment Currency:USD,EUR,CAD,HKD,CNY...

Accepted Payment Type:T/T,L/C,Western Union,Cash,Escrow...

Language Spoken:English,Chinese

7. How can get theshipping cost?

If you tell us your destination port or delivery address, we will check cost by sea/air according to geographical location.

8.Do youoffer OEM service?

Weoffer OEM custom service, if quantity is large.Our factory is experienced enough to serve you well.

9.What's theMOQ?

1 set,some products require a minimum order quantity.

10.How long is yourdelivery time?

Delivery within5-30 days after receipt of payment,delivery may be a little later for large or customized products, but not much later.

11.Do you offersample service?

Yes,the sample freight needs to be paid by the customer.

12.Where's yourgeneral loading port?

Shanghai port/Guangzhou port forLCL or FCL or as your requirement.Product Catalog