WG series pulsating vacuum sterilizer uses saturated steam as sterilization medium, and releases a large amount of latent heat and humidity when the saturated steam condenses, so that the articles to be sterilized are in high temperature and moist state, and after a period of heat preservation, the sterilization purpose is achieved. Pulsating vacuum exhaust was used to eliminate the influence of cold air on temperature. Finally, vacuum dehumidification combined with jacket drying was used to dry sterilized articles.

WG series pulsating vacuum sterilizer is mainly used for sterilization of medical instruments, dressings, rubber, officinal instruments, implantable instruments and liquids in hospital disinfection supply room, third party disinfection supply center and operating room.

Main Parameters and Utilities

| Inner chamber design pressure | -0.1~0.3MPa | Opening pressure of inner chamber safety valve | 0.28 MPa |

| Jacket design temperature | 0.3Mpa | Opening pressure of jacket saety valve | 0.28 Mpa |

| Design temperature | 150ºC | Temperature control precision of sterilization temperature | 0~2ºC |

| Max.working temperature | 139ºC | Temperature uniformity | ±1ºC |

| Max.working pressure | 0.25MPa | Amplitude and times of vacuum pulsation | Amplitude -80~0Kpa, times 1~99 |

| Vacuum leakage rate | ≤0.13Kpa/min | Times of cross pressure pulsation | Amplitude -80~80Kpa, times 1 |

| Limit vacuum | -97Kpa | Positive pressure pulsation times | 1~3 |

Size & Utilities

Model | Tank size | Volume (L) | Dimensions L×W×H(mm) | Weight (Kg) | Steam consumption (kg/C) | Water Consumption(kg/C) | Power supply | Power | |

| W×H (mm) | Depth (mm) | ||||||||

| WG-0.25 | 550×550 | 850 | 255 | 1250×1280×1850 | 750 | 18 | 120 | 380v,50hz | 2KW+24KW |

| WG-0.36 | 610× 610 | 1000 | 360 | 1300×1350×1850 | 850 | 22 | 180 | 380v,50hz | 2KW+30KW |

| WG-0.6 | 610× 910 | 1200 | 600 | 1500×1440×1960 | 1250 | 35 | 320 | 380v,50hz | 3KW+36KW |

| WG-0.8 | 610× 910 | 1500 | 800 | 1800×1440×1960 | 1350 | 47 | 400 | 380v,50hz | 3.5KW+48KW |

| WG-1.2 | 680×1180 | 1500 | 1200 | 1800×1480×2000 | 1650 | 65 | 600 | 380v,50hz | 3.5KW |

| WG-1.5 | 680×1180 | 1850 | 1500 | 2140×1480×2000 | 1850 | 80 | 750 | 380v,50hz | 4KW |

| WG-2.0 | 900×1390 | 1620 | 2000 | 1970×1750×2200 | 2300 | 106 | 1000 | 380v,50hz | 4.5KW |

| WG-2.5 | 900×1390 | 2050 | 2500 | 2350×1750×2200 | 2700 | 132 | 1250 | 380v,50hz | 6KW |

| WG-3.0 | 900×1390 | 2400 | 3000 | 2700×1750×2200 | 3500 | 132 | 1250 | 380v,50hz | 8KW |

Body of the sterilizer:

*It is designed and manufactured in accordance with GB/T150 "the Pressure Vessel", GB 8599 "The Technical Requirements of Large Steam Sterilizer--Automatic Control Protocol", and TSG 21-2016the "Safety and Technology Specification for Fixed Monitor Vessels" and related inspection procedures.

*The main structure is a rectangular section, European ring stiffener jacket structure. The door sealing mode is pneumatic sealing, and the interlock of double doors fully meets the specification requirements.

*The inner liner, door plate and other materials in contact with steam are S30408 stainless steel, the design life can reach 10 years, 20000 sterilization cycles (316L stainless steel is optional, the design life is 15 years, 30000 sterilization cycles), the front teeth and main block teeth are S30408 stainless steel, the jacket is made of high-quality Q245R, and the special material for pressure vessel is S30408.

*The equipment has standard GMP authentication interface.

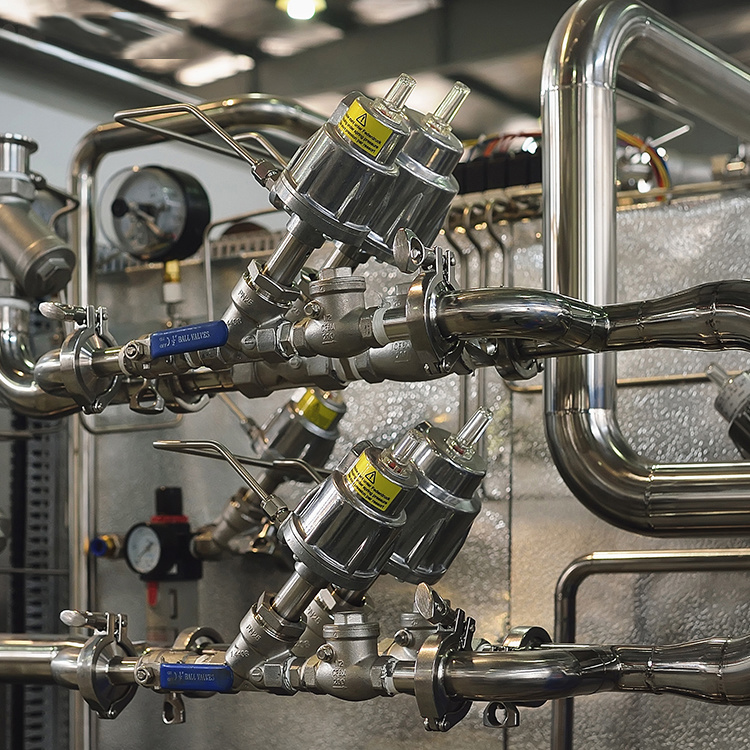

Sterilizer pipingsystem:

*304 stainless steel sanitary pipeline, clamp type connection. German Gem-u angle seat pneumatic valve, Taiwan Yadeke solenoid valve and German speck direct connected water ring vacuum pump are adopted.

*(Optional) Intelligent automatic drainage system, water saving and noise reduction system and pipeline insulation treatment.

Sterilizer control system:

*It adopts imported Siemens programmable controller PLC and color touch screen at the operation end; the printer can print the process data of each stage in real time; various safety and alarm systems are adopted.

* It has a communication interface connected with the quality traceability system of the disinfection and supply center. Intelligent maintenance system, (optional) remote monitoring and maintenance module.

* The compound pulsating process can eliminate indoor air more thoroughly, improve the fatigue life of the equipment and achieve good drying effect.

Details