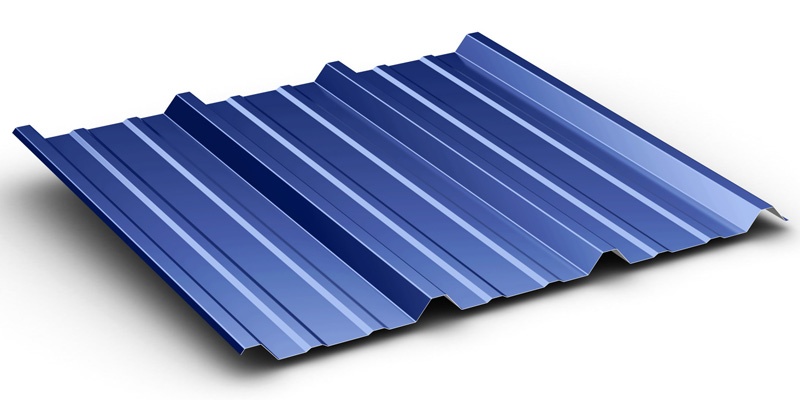

IBR 840 ibr metal sheet roof panel roll forming machine/roof press making machine

this profile is more popular profile.

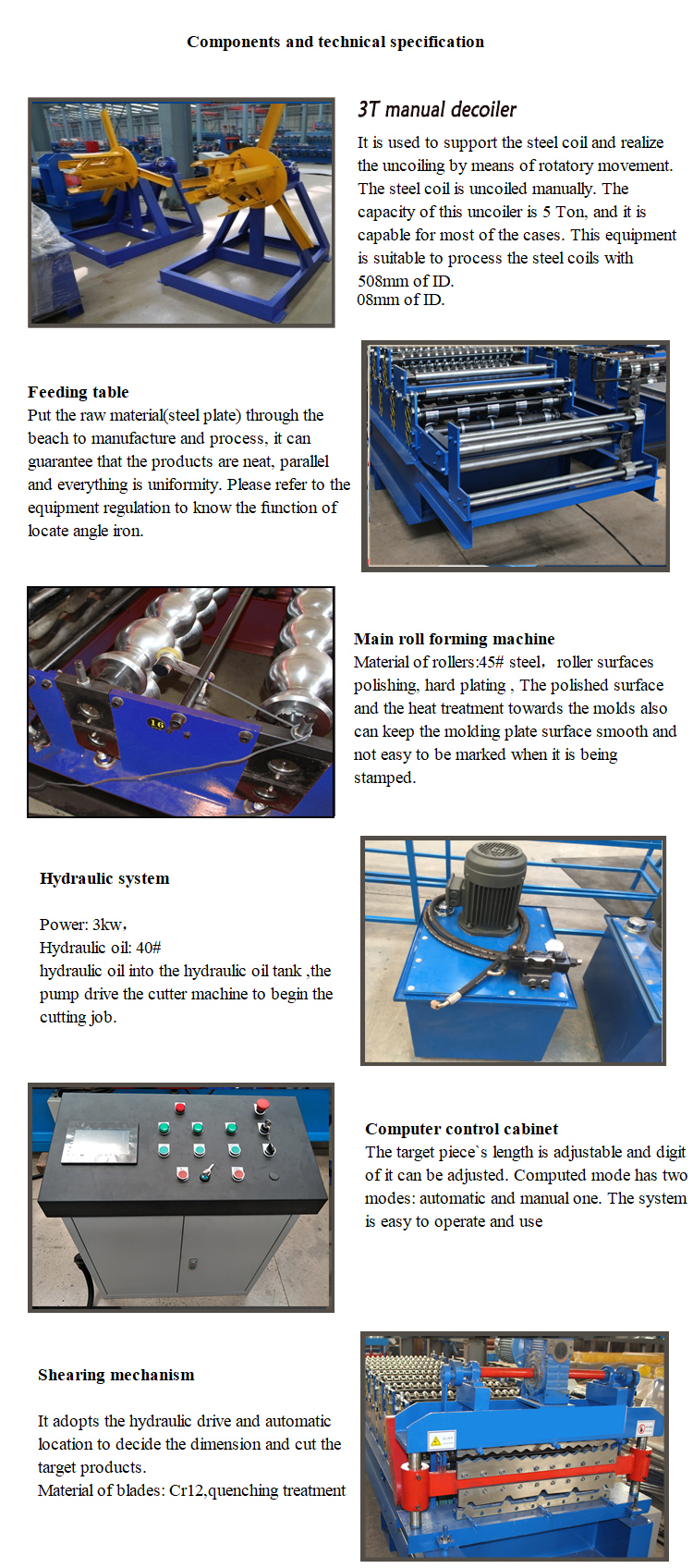

Roof tile making machine consists of uncoiler and its base,infeed guides,fixed position driven forming stations,pressing die,shearing device,hydraulic station,PLC control console and so on.Our company has dozens of profile models for this series roll forming machine,We can design different kinds of profile and fittings for machine,as per customers’ requirement.

1Suitable materialcolor steel sheet, galvanized steel sheet, aluminium sheet

2Material width your required

3Material thickness0.3-0.8 or as your required

4Working speed8-12m/min, can be 20-25m/min

5Main motor power 4kw with cycloidal with reducer

6Hydraulic pump power4kw

7Electrical control systemPLC control system with inverter

8Shaft diameter70/75mm

9Roller station8/9/10/11 rows, depend on your panel profile drawing

10Rollerhigh grade 45# steel, hard chrome plating

11Working time24 hours

12workers1-2 only

13Cutting head materialCr 12 mould steel with quenched treatment

14Voltage380V 3Phase 50Hz or as your required

15The machine size5800mm*1400mm*1350mm

Our Company Main Roll Forming machines

1. Different types of roof profile drawing forming machine ;

2. Curve roof roll forming machine; 3. Ridge cap roll forming machine;

4. Floor deck roll forming machine; 5. Rain gutter roll forming machine;

6. Downpipe roll forming machine; 7. Highway guardrail roll forming machine;

8. Roller shutter door forming machine; 9. Door frame roll forming machine;

10. CZU purlin roll forming machine; 11. Light keel roll forming machine;

12. Slitting machine (lines); 13. Shearing/bending machine;

14. Decoiler(Hydraulic decoiler, electric decoiler and manual decoiler) and so on

How to Contact with us:

Tel&Whatsapp:+86-15612977437

Email:abby@hbsxmachinery.com